Imagine this: You’re sitting cozy in your living room during a fierce storm, rain pounding against the windows. Suddenly, you hear a flap—your roof shingles are lifting off like leaves in the wind. Why? Often, it’s because someone skimped on the nails. Poor choices lead to big problems, like leaks and costly repairs. But don’t worry, reader—I’ve got you covered.

So, what type of nails are typically used for roofing? The short answer is galvanized steel nails. These come with large heads and often ring shanks for a solid grip. They hold everything from shingles to underlayment in place, fighting off wind and water like champions.

You might wonder why these nails rule the roofing world. It’s all about their ability to resist rust. Roofs face endless exposure to rain, snow, and humidity, so you need nails that won’t corrode and weaken over time. Galvanized nails have a special zinc coating that acts as a shield, protecting the steel core.

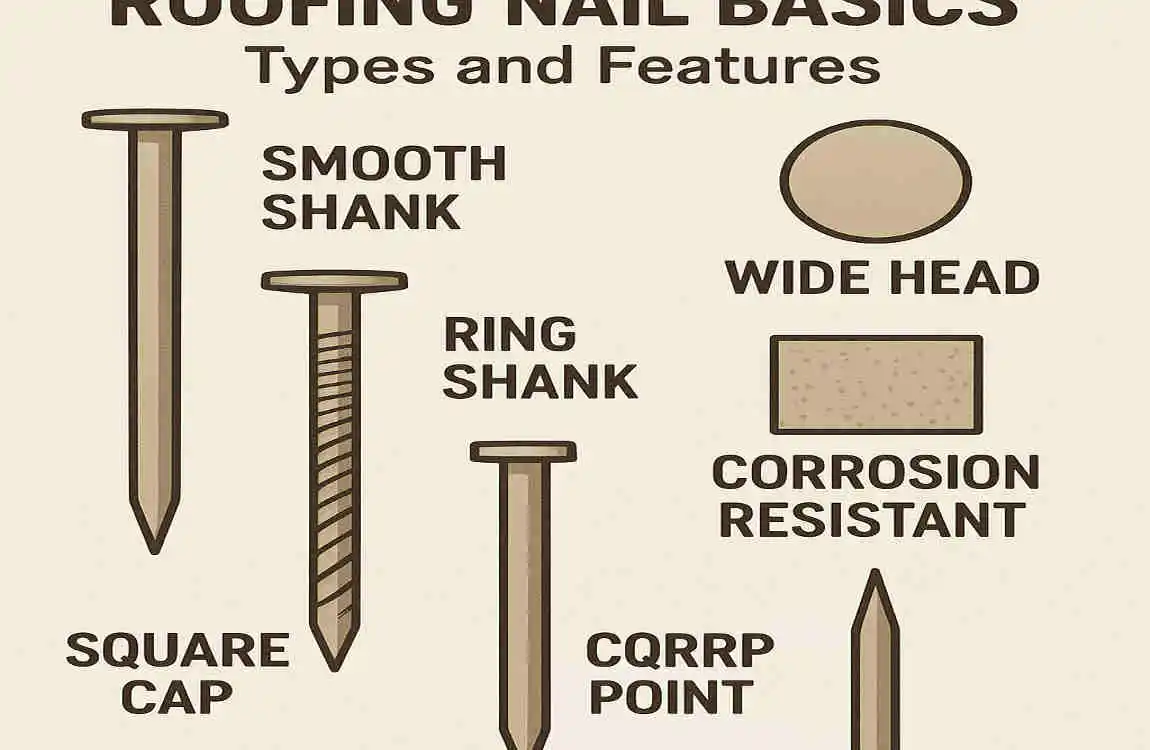

Roofing Nail Basics: Types and Features

Roofing nails might look simple, but they pack a punch in keeping your roof secure. At their core, these nails are made of steel, usually in 11- or 12-gauge12-gauge thickness. That’s about as thick as a standard paperclip wire, but way stronger. Most measure 1 to 1.25 inches long, making them perfect for asphalt shingles, the most common roofing material.

Why do these specs matter? Well, the gauge affects strength—thicker means tougher. Length ensures the nail penetrates deep enough into the roof deck without poking through unnecessarily. You want that sweet spot for maximum hold without waste.

Let’s talk heads. The head of a roofing nail is like its crown—it spreads out the force and keeps materials flat. Large flat heads work great for general use, providing a wide surface to press down on shingles. They prevent tearing and make installation smooth.

On the flip side, diamond-point heads add extra resistance against pull-through. Picture a nail that bites into the wood like a determined dog with a bone. These are ideal if you live in areas with strong winds that might try to yank your shingles away.

Now, shanks—the body of the nail. This is where things get interesting. Smooth shanks slide in easily, making them a favorite for softwood roofs. They’re straightforward and quick to drive, but they might not grip as tightly in tougher spots.

Step up to ring shanks, and you’re in high-performance territory. These have deformed ridges that lock into the wood, offering superior pull-out resistance. It’s like adding Velcro to your nails—once in, they’re hard to budge.

For the ultimate hold, consider spiral shanks. They twist as you hammer them in, creating a screw-like grip. Pros love these for demanding jobs where nothing can afford to loosen up.

Materials-wise, steel is the base for most. But here’s the key: it’s almost always galvanized. That zinc layer prevents rust, which is crucial since roofs get wet often. Without it, your nails could turn into crumbly messes in no time.

Curious about which type fits your roof? Think about your climate and materials. In wet areas, go for something with extra grip. Dry spots? Smooth might suffice.

To make this more straightforward, here’s a handy table comparing common types:

Type Best Use Pros Cons Focus Keyword Fit

Smooth Shank Asphalt shingles Easy drive-in Less grip in hardwood General roofing.

Ring Shank High-wind areas Superior pull-out resistance Harder to remove Best galvanized

Coil Roofing Nails Pneumatic nailers Bulk fastening Requires gun Pro installs.

See how ring shanks shine for harsh conditions? That’s why they’re often the best galvanized roofing nails for windy zones.

Why Galvanized Nails? Corrosion Protection Explained

Ever wondered why rust is a roof’s worst enemy? Moisture sneaks in, reacts with plain steel, and boom—your nails weaken, shingles loosen, and leaks start. That’s where galvanized nails come to the rescue. They get a protective zinc coating that blocks rust, keeping your roof sturdy for years.

How does this magic happen? Galvanization bonds zinc to steel, creating a barrier. When water hits, the zinc sacrifices itself first, leaving the steel intact. It’s like a bodyguard taking the hit for you.

There are two main ways to galvanize: hot-dipping and electro-galvanizing. Hot-dipped galvanized nails are dipped into molten zinc, forming a thick, durable coating. This can last 50 years or more, even in rainy climates. Think of it as heavy-duty armor for your roof.

Electro-galvanized nails, on the other hand, use electricity to apply a thinner zinc coat. They’re shinier and cheaper, great for milder weather. But in harsh spots? They might not hold up as long.

Why choose galvanized over others? Alternatives like aluminum nails are lightweight and rust-resistant, especially near the coast. But they’re softer, so they bend easier. Stainless steel nails? Super tough against corrosion, but they’ll empty your wallet.

Building codes often demand galvanized nails. The International Residential Code (IRC) says so for good reason—it ensures safety and longevity. Skip this, and you risk voiding warranties or facing inspections.

Picture this: You’re in a humid area, and you pick non-galvanized nails. A few seasons later, rust spots appear, and your roof sags. Not fun, right? Galvanized prevents that nightmare.

For coastal homes, hot-dipped options are king. They handle salt spray better than electro types. Always check your local weather— it guides your choice.

Best Galvanized Options for Your House

Now that we’ve covered the why, let’s get to the good stuff: picking the best galvanized roofing nails for your home. With so many options, it helps to rank them by durability and use. Trust me, the right choice means fewer headaches down the road.

Top of the list? Hot-dipped galvanized nails. These bad boys have that thick zinc layer we talked about, making them ideal for harsh weather. They’re perfect for securing asphalt shingles and felt underlayment. Brands like Maze or Grip-Rite offer reliable versions that pros swear by.

Why are they the top pick? In storms, they hold firm. Their coating lasts for decades, reducing the risk of rust. If you live in a rainy or snowy area, these are your go-to. Plus, they come in various roofing nail sizes, from 1 to 1.5 inches.

Next up: Electro-galvanized nails. These have a thinner, shinier coat, making them budget-friendly for suburban homes with milder climates. A common size is 1.25 inches, great for standard shingle jobs. They’re easy on the wallet but still provide solid corrosion resistance.

In high-wind zones, ring-shank galvanized nails steal the show. Combine the ring design with galvanization, and you get an unbeatable grip. Hot-dipped versions are best here, as they add extra longevity.

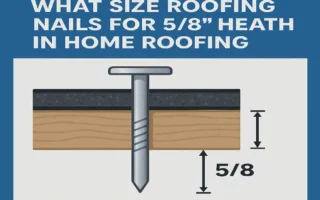

Let’s break down sizes. Use 1-inch nails for underlayment— they secure felt without over-penetrating. For shingles, go 1.25 to 1.5 inches to ensure at least 3/4-inch deck penetration. Too short? Your roof could fail in the wind. Too long? Wasteful and risky.

Buying tips: Look for ASTM F1667 standards— that’s your quality guarantee. Avoid electro-galvanized with treated lumber; the chemicals can eat away the thin coating faster.

Here’s a comparison table to help you decide:

Product/Type Coating Size Options Price Range (per lb)Best For

Hot-Dipped Galv. Thick zinc 1-1.5″ $0.10-0.20 All climates

Electro-Galvanized Thin zinc 1.25″ $0.05-0.15 Mild weather

Ring Shank Galvanized Thick/thin 1.25″ $0.15-0.25 Windy areas

See? Hot-dipped wins for versatility. For your house, match the nail to your needs. Coastal? Hot-dipped. Budget project? Electro.

Reader, what’s your climate like? If it’s tough, hot-dipped galvanized roofing nails could be your best bet. Check out our [galvanized nail buying guide] for more details.

Don’t forget coil versions for pneumatic guns—they speed up big jobs. Galvanized coils keep pros efficient without sacrificing quality.

In windy spots, combine ring shanks with hot-dipping for ultimate peace of mind. Your roof will thank you.

For metal roofs, longer galvanized nails (up to 2 inches) work best, often with ring shanks for extra hold.

Ultimately, the best galvanized roofing nails depend on your setup. Prioritize quality, and you’ll build a roof that lasts.

Installation Tips for Long-Lasting Results

Installing roofing nails correctly is key to a leak-free home. Mess it up, and you’re inviting trouble. But follow these steps, and you’ll nail it—pun intended.

First, match the nail length to your materials. Add shingle thickness plus at least 3/4 inch for deck penetration. For example, standard asphalt shingles? Grab 1.25-inch hot-dipped galvanized nails. This ensures a firm anchor without gaps.

Spacing matters too. Place nails 6 to 8 inches apart at edges, where wind hits hardest. In the field (middle areas), space them 12 inches. Follow your shingle manufacturer’s specs—they know best.

Tools make a difference. For minor repairs, a hammer works fine. But for full roofs, use a pneumatic gun with coil nails. It saves time and reduces fatigue. Just ensure your nails are galvanized to prevent rust.

Common mistakes? Using undersized nails—they pop out in storms. Or skipping galvanization in wet areas, leading to corrosion and leaks. Always double-check.

Step-by-step guide:

- Prep your surface: Lay underlayment flat.

- Position shingles: Align them properly.

- Drive nails: Angle slightly for better hold, but not too much.

- Seal if needed: For valleys, add extra fasteners.