Imagine this: a heavy rainstorm hits your neighbourhood, and suddenly, you notice water dripping through your ceiling. You trace the leak back to your corrugated roof sheets — those wavy metal panels you thought were secure. It’s a frustrating and urgent problem that threatens the safety and comfort of your home.

The good news? You don’t always need to call a costly professional to fix these issues. With the right tools, safety precautions, and some patience, you can perform DIY corrugated roof fixes that save you thousands of rupees. In fact, metal roofs can last 40 to 70 years with proper maintenance and timely repairs.

Common Issues with Corrugated Roof Sheets

Corrugated roofing is sturdy, but it faces several common challenges that affect its performance over time. Understanding these problems helps you act quickly before they escalate.

Dents and Buckling

Hailstorms or even walking on the roof can cause dents and buckling in the metal sheets. These dents aren’t just cosmetic; they create low spots where rainwater can pool. Standing water accelerates corrosion and invites leaks, so it’s important not to ignore these dents.

Rust and Corrosion

Rust is a major enemy of metal roofs, especially in humid or coastal areas. For example, during Lahore’s monsoon season, moisture and airborne salt accelerate corrosion. Rust weakens the metal and eventually creates holes. If you spot orange or brown stains on your roof panels or inside your home, it’s a sign of rust.

Loose or Missing Fasteners

Over time, the screws and nails holding your roof down can loosen or even fall out completely. When fasteners fail, the panels shift or flap in the wind, creating leaks. Additionally, the overlaps between sheets may separate, allowing water to sneak in during heavy rains.

Noise and Expansion Cracks

Metal expands and contracts with temperature swings. This natural movement can cause noise, such as popping or creaking. Sometimes, it leads to small cracks along the seams or fastener holes, which can worsen if left unattended.

Warning Signs to Watch For

- Water stains or discolouration on your ceiling or walls

- Granule buildup or debris in gutters indicates roof wear

- Sagging or uneven panels may indicate structural issues

Ignoring these signs could lead to expensive structural repairs costing upwards of 500,000 PKR down the line!

Tools and Materials Needed

Getting your toolkit ready is the first step toward a smooth, safe repair process. Here’s what you’ll need to fix corrugated roof sheets efficiently:

Safety Gear

- Harness and secure anchor points

- Non-slip shoes for stable footing

- Gloves to protect your hands from sharp metal edges

- Safety goggles to shield your eyes from dust and debris

Repair Tools

- Cordless drill or screw gun with magnetic bits (for easy screw handling)

- Rubber mallet (to gently fix dents without damaging the metal)

- Wire brush (for rust removal)

- Ladder sturdy enough for your roof height

- Tin snips (to cut replacement sheets or patch material)

- Putty knife (for applying sealants or patches)

Materials

- Replacement corrugated sheets

- Self-tapping screws with neoprene washers (to prevent leaks)

- Rust converter and protective sealant

- Foam closures for eaves and ridges to block water and pests

Budget Tip

You can assemble this core repair kit for under 30,000 PKR by sourcing materials from local markets in Pakistan. This investment saves money in the long run and prepares you for future fixes.

Safety Precautions Before Starting

Your safety should always come first. Roof repairs involve heights, sharp tools, and sometimes unpredictable weather. Follow these precautions to minimise risks:

- Inspect on dry days only. Wet roofs are slippery and dangerous.

- Use a spotter when climbing the ladder to steady it.

- Wear your harness and secure it to a sturdy anchor point.

- Avoid steep roofs with a pitch over 6:12 unless you are very experienced.

- Check the weather forecast: avoid working on windy, rainy, or extremely hot days (metal expands in heat, increasing the risk of injury).

Pro advice: If your roof is older than 10 years or higher than a single-story home, consider hiring a certified professional. Falls are the leading cause of DIY roof injuries.

Step-by-Step Guide: How to Fix Corrugated Roof Sheets

Inspect and Prepare

Start safely by climbing up with all your gear. From inside your home, trace the leak points and mark damaged areas on the roof with chalk. Look for dents, rust patches, and loose screws.

Clear off all debris—leaves, dirt, or old sealant—to get a clean surface. If your roof feels uneven, use the 3-4-5 method (a simple right-angle measurement technique) to check and realign panels as needed.

Address Rust and Dents

Use a wire brush to remove loose rust and dirt from affected areas. Apply a rust converter to stop corrosion and prevent further damage.

For dents, gently tap with a rubber mallet from the underside or, if accessible, from the side. Avoid pounding too hard — overworking the metal can weaken it or cause cracks.

Secure Loose Panels

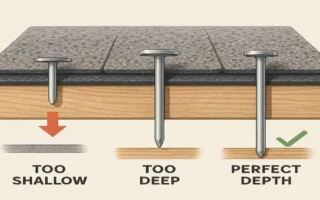

Remove old or damaged fasteners carefully. Reinstall screws in a checkerboard pattern for better hold — place screws in the high points of every wave and in the low points every two waves.

Make sure the screws are snug but don’t strip the holes. Using a cordless drill with magnetic bits makes this quick and less frustrating.

Repair Leaks and Overlaps

Apply a high-quality sealant along seams and screw holes to block water entry. When adding new sheets, overlap them by 4 to 6 inches to ensure proper runoff.

Install foam closures at the eaves and ridge to prevent water, dust, and pests from getting underneath your panels.

Replace Damaged Sheets

If a panel is beyond repair, unscrew it carefully to avoid damaging adjacent sheets. Slide in the new sheet, aligning the corrugations perfectly with existing panels.

Fasten the new sheet with screws spaced 18 to 24 inches apart and at least 6 inches from the sheet edges to prevent splitting.

Advanced Tips for Durable Repairs

Climate-Specific Adjustments

In Pakistan’s intense heat, apply heat-resistant coatings after repairs. These reduce metal expansion and UV damage, prolonging your roof’s life.

Prevent Future Problems

- Conduct annual inspections to catch small issues early.

- Keep gutters clean to prevent water backup and rust formation.

When to Consider Upgrading

If more than 30% of your roof is damaged, a full replacement might be more cost-effective than ongoing repairs. This decision depends on roof age, condition, and your budget.

Cost Breakdown and DIY vs. Pro

Repair Type DIY Cost (PKR)Pro Cost (PKR)Time

Minor Dent/Rust 2,000 – 5,000 10,000+ 2 – 4 hours

Panel Replacement 5,000 – 15,000 20,000 – 50,000 1 day

Full Section Fix 20,000+ 50,000+ 2 – 3 days

DIY repairs can save you 60-70% of costs, but professionals offer warranties and handle complex problems faster.