Imagine this: you just finished installing a brand-new roof with 5/8″ sheathing, but weeks later, you spot leaks and loose shingles. What went wrong? One of the most common culprits is using the wrong size roofing nails for 5/8 sheathing. It’s a simple mistake that can lead to weak roofs, building code issues, and expensive repairs.

Roofing Sheathing Basics: Understanding 5/8″ Thickness

Before diving into nail sizes, it’s important to understand what 5/8″ sheathing actually is and why it matters.

Sheathing refers to the panels—usually plywood or OSB (oriented strand board)—attached to your roof’s rafters or trusses. This layer supports the roofing material and transfers loads like wind, snow, and foot traffic down to the structure.

Why 5/8″ Sheathing?

Most residential roofs use either 1/2″, 7/16″, or 5/8″ thick sheathing. The 5/8-inch thickness is prized for its:

- Greater strength and stiffness compared to thinner panels.

- Better load resistance, especially in areas prone to heavy snow or strong winds.

- Compliance with stricter building codes in hurricane or seismic regions, where durability matters most.

For instance, if you live in a hurricane-prone area like Florida or along the Gulf Coast, 5/8″ plywood or OSB is often the minimum recommended thickness for your roof sheathing.

Sheathing Installation Overview

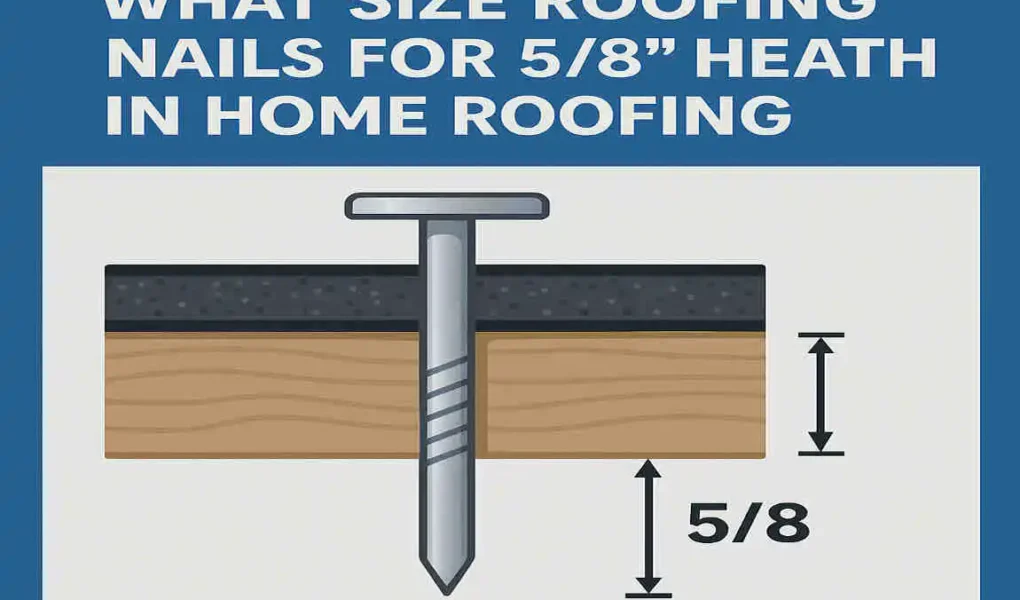

Installing 5/8″ sheathing involves careful spacing and orientation. Panels usually run perpendicular to rafters, nailed or screwed down at regular intervals. The size of the roofing nails is crucial because they need to:

- Penetrate fully through the sheathing.

- Embed sufficiently into the underlying rafters or trusses for a strong hold.

- Resist pull-out forces caused by wind uplift or other stresses.

Think of it as the difference between a nail that just grazes the wood versus one that bites in solidly.

Building Codes: Official Nail Size Requirements for 5/8″ Sheathing

To ensure safety and durability, building codes provide clear rules on nail size and penetration for roof sheathing. Let’s look at some key standards:

Code Reference Minimum Nail Size for 5/8″ Sheathing Penetration Requirement Notes

IRC R602.3 8d common (2-1/2″ x 0.131″) 1-1/4″ into framing Applies to residential roofs

IBC 2304.9.1 8d or 10d ring-shank. At least 1.5x sheathing thickness. Required in high-wind zones

NRCA Guidelines 1-1/4″ to 2-1/2″ shank Minimum 3/4″ penetration into rafter specifically for asphalt shingles

What Does This Mean for Your Roof?

- The standard nail size for 5/8″ sheathing is an 8d nail, 2-1/2 inches long.

- Nails must penetrate at least 1-1/4 inches into the framing member to ensure a secure hold.

- In areas with high wind or seismic activity, codes often require ring-shank nails or longer nails (10d) for extra grip.

Common Code Myths

Many try to cut corners by using shorter 6d nails (2 inches), thinking it saves time or money. But this nail length doesn’t meet penetration requirements and can lead to:

- Nails pulling out during storms.

- Violations during inspections.

- Costly roof failures.

Types of Roofing Nails and Best Fit for 5/8″ Sheathing

There are many roofing nail types, but which one fits 5/8″ sheathing best? Let’s compare.

Nail Type Size Recommendation Best For 5/8″ Sheathing?Shank Style Pros and Cons

Common 8d (2-1/2″) Yes, basic hold Smooth Affordable, widely available Less pull-out resistance

Ring-Shank 8d-10d (2-1/2″ to 3″) Ideal, superior grip Ringed Excellent pull-out strength Slightly more expensive

Spiral 7d-8d (2-1/4″ to 2-1/2″) Good for softwoods. Spiral: Good holding power. Not common for roofing

Galvanized Any above Corrosion resistance Hot-dipped Durable in humid/coastal areas Costlier

Top Recommendation: What Size Roofing Nails for 5/8″ Sheathing?

For most residential roofs, 2-1/2 inch 8d ring-shank nails are the gold standard. They offer the perfect balance of length and grip, embedding deeply into rafters and resisting wind uplift.

Material Matchups

- If your framing is cedar or pressure-treated lumber, galvanized nails are essential to prevent rust and corrosion.

- For coastal or humid climates, hot-dipped galvanized nails improve roof longevity.

- When using pneumatic nail guns, try to use nails with a gauge between 11 and 12 for smooth firing.

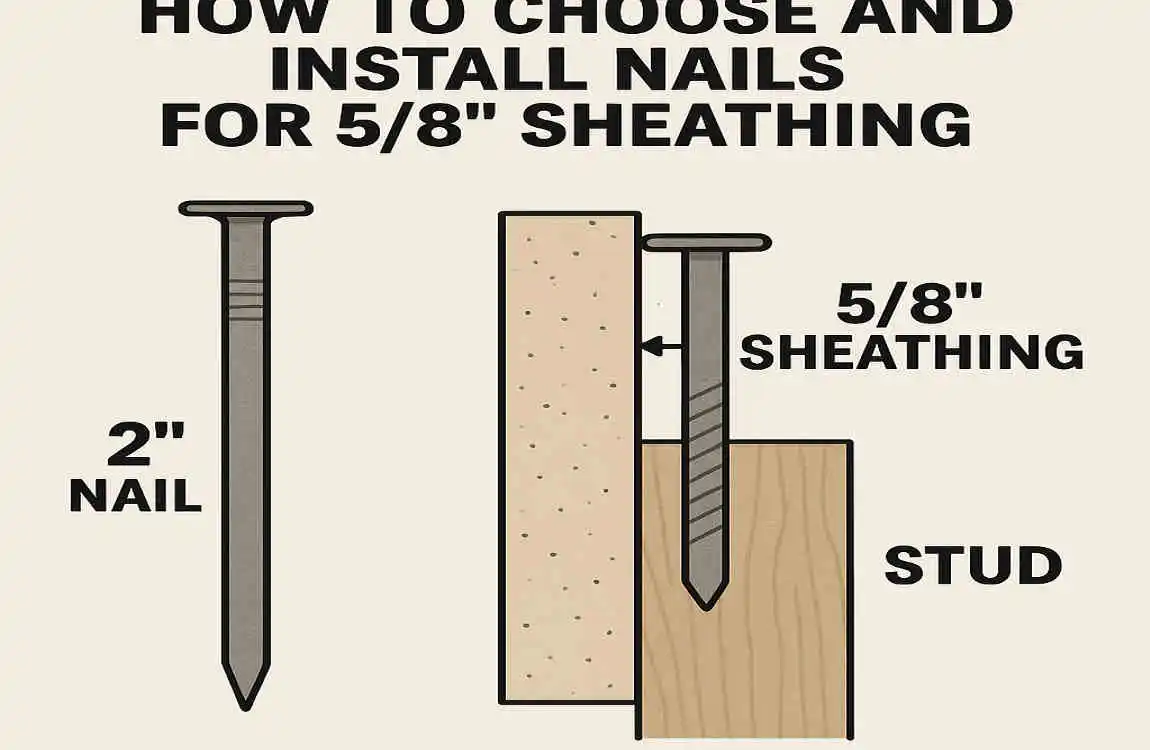

Step-by-Step: How to Choose and Install Nails for 5/8″ Sheathing

Ready to nail your roof like a pro? Here’s a simple guide to make sure you get it right.

Measure Your Setup

- Confirm your sheathing thickness is 5/8″.

- Check rafter spacing — common spacings are 16″ or 24″ on center (OC). This affects nail spacing.

Select Nail Size

Use this simple formula:

Nail length = Sheathing thickness (5/8″) + Minimum penetration (1-1/4″) + 1/2″ extra allowance

This leads you to nails about 2-1/2 inches long.

Nailing Pattern

Follow IRC guidelines:

- Nails every 6 inches along panel edges.

- Nails every 12 inches in the field (center area).

Tools and Techniques

- Use a roofing nail gun with PSI settings adjusted for 5/8″ sheathing density.

- If hand nailing, drive nails flush but avoid overdriving (countersinking weakens hold).

- Keep nails straight and evenly spaced for best results.

Common Mistakes and How to Avoid Them

Even seasoned roofers slip up sometimes. Here’s a quick look at common errors and how to fix them:

- Using undersized nails (e.g., 2″ nails): These nails don’t penetrate enough and can pull through sheathing.

- Ignoring climate conditions: Humid or coastal environments need galvanized nails to prevent rust.

- Over-nailing: More nails don’t mean stronger roofs. It wastes material and can split wood, weakening the structure.

Quick Fix Checklist

- Always use a minimum of 2-1/2″ length nails for 5/8″ sheathing.

- Use ring-shank or spiral nails for extra grip in high-wind zones.

- Switch to galvanized nails in areas with saltwater or high humidity.

- Follow nailing patterns per code.

- Check installation with pull-out tests on scrap wood.

Pro Tips from Roofing Experts for 5/8″ Sheathing Success

- Upgrade to coated nails for about 30% better holding power than plain steel nails.

- Test the pull-out strength on scrap pieces before starting your job. It saves headaches later.

- Buying nails in bulk (8d ring-shank) can save you money in the long run—quality nails reduce callbacks.

- As one experienced contractor puts it:

- “The right nails saved my 5/8″ roof during the last monsoon season. No leaks, no issues.”