Did you know that metal roofs without proper insulation can lose 20-30% more energy compared to insulated roofs? This inefficiency results in higher utility bills, uncomfortable indoor temperatures, and potential damage from condensation. The good news is that by learning how to insulate a metal building roof, you can reduce energy consumption by up to 30-50%, translating into significant savings.

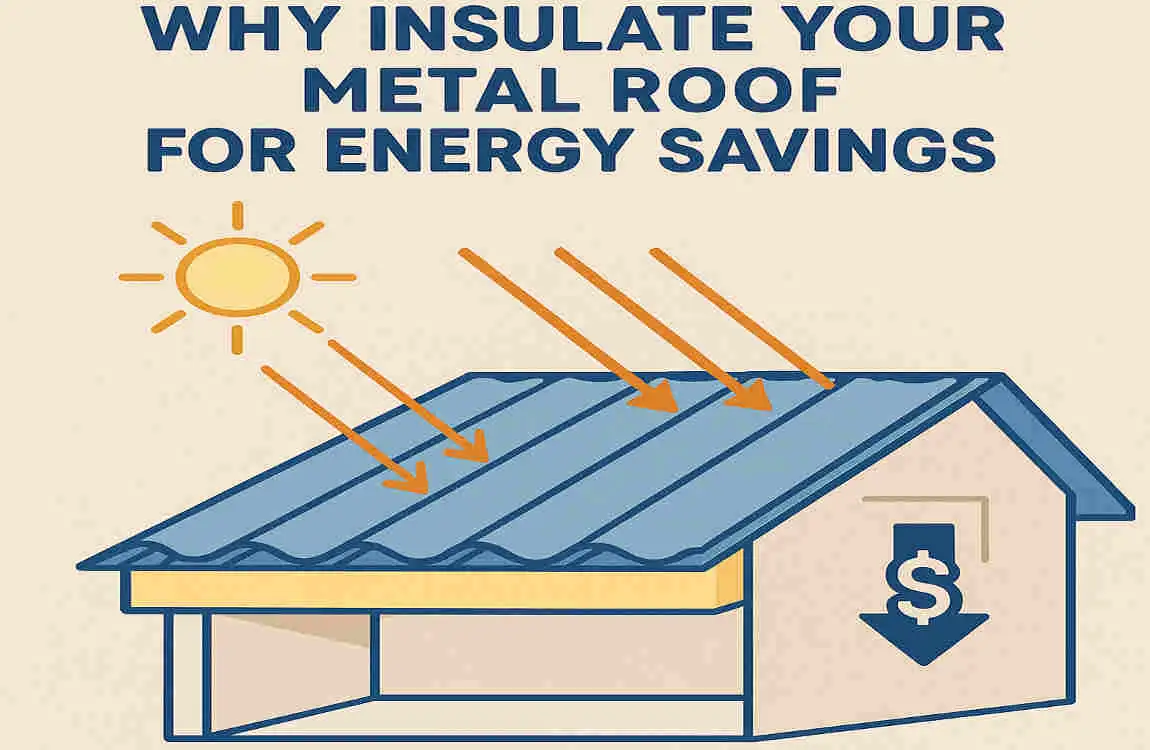

Why Insulate Your Metal Roof?

Energy Savings Explained

Metal buildings, due to their conductive nature, are prone to rapid heat gain in summer and heat loss in winter. This means your HVAC system works overtime, driving up energy bills. Insulation acts as a barrier, reducing heat transfer between the inside and the outside.

A key way to measure insulation effectiveness is the R-value, which indicates resistance to heat flow. The higher the R-value, the better the insulation. Choosing the right R-value depends on your local climate:

- Hot climates require insulation that reflects heat and prevents it from entering.

- Cold climates need insulation that keeps heat inside to reduce heating costs.

Understanding these basics helps you pick the right insulation type for your metal roof.

Additional Benefits

Insulating your metal roof isn’t just about saving energy. Here are some other perks:

- Noise Reduction: Metal roofs can amplify the sounds of rain and hail. Proper insulation cuts noise by up to 50%, making your space more comfortable.

- Condensation Prevention: Without insulation, moisture can build up under your roof, causing rust and structural damage. Insulation helps keep your building dry.

- Increased Property Value: Energy-efficient buildings attract buyers and tenants. A well-insulated metal building can boost your property’s resale or rental value.

Types of Insulation

Choosing the best insulation for metal building roofs depends on factors like climate, budget, and installation preferences. Here’s a quick comparison table to help you decide:

Type R-Value per Inch Pros Cons Cost per sq ft

Spray Foam 6-7 Seals gaps, airtight. Expensive, requires pro install $1 – $3

Rigid Foam Boards 4-6 Durable, high resistance Cutting required $0.50 – $1.50

Fiberglass Batts 3-4 Affordable, easy DIY Can compress if not installed properly $0.30 – $0.80

Reflective Foil N/A (radiant) Reflects heat, great in hot climates. Less effective in cold climates $0.40 – $1

Which Insulation Should You Choose?

- Hot Climates: Combine reflective foil with spray foam for the best energy savings.

- Moderate to Cold Climates: Spray foam or rigid foam boards offer high R-values and moisture resistance.

- On a Budget: Fiberglass batts are affordable and DIY-friendly but require careful installation.

Tools and Materials Needed

Before you start your insulation project, gather the right tools and materials to make the process smoother and safer:

- Safety gear: Gloves, goggles, dust mask

- Measuring tape: For accurate insulation cutting and placement

- Adhesive or staples: To secure insulation materials

- Ventilation tools: Especially important for spray foam insulation to ensure proper airflow during and after installation

- Utility knife and straight edge: For cutting rigid foam or batts

- Ladder and scaffolding: For safe roof access

Make sure to have all these handy before you begin your project!

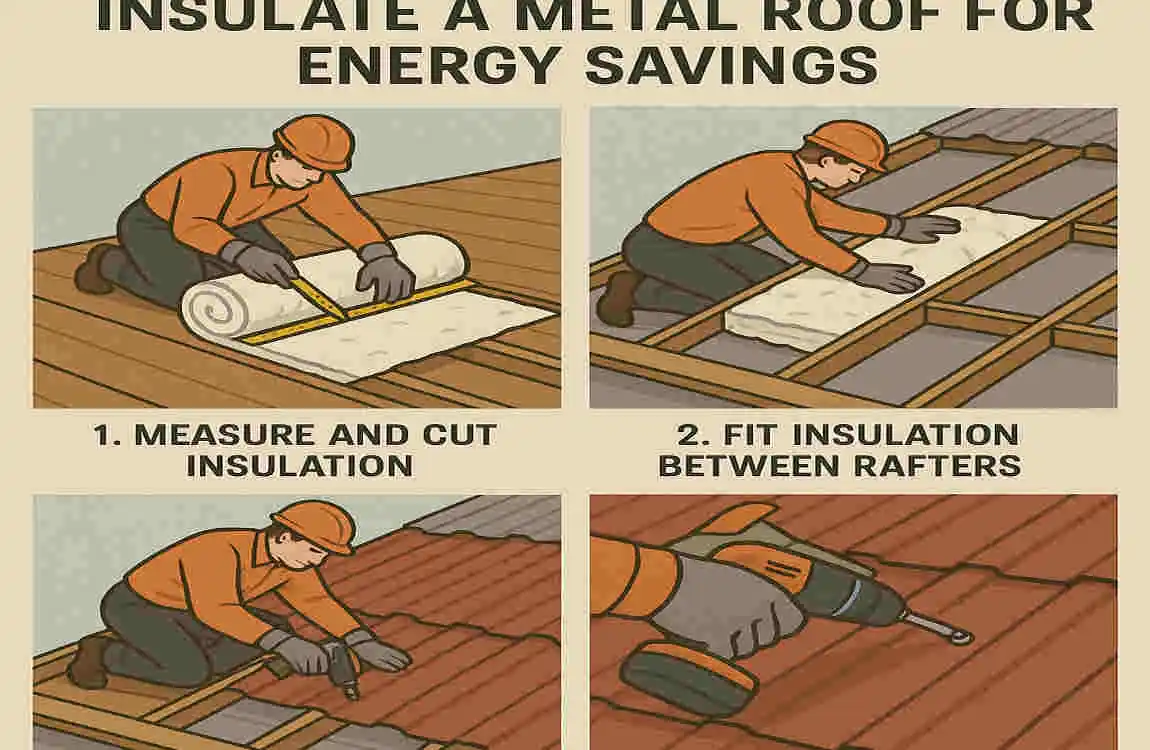

Step-by-Step Installation Guide

Preparation Steps

Start by inspecting your metal roof carefully:

- Check for leaks, rust, or damaged panels.

- Clean the purlins (the horizontal supports) where insulation will be attached.

- Ensure the roof is completely dry.

This prep work is crucial for a long-lasting insulation job.

DIY Methods

Here’s how you can insulate your metal roof yourself using different methods:

- Fiberglass Batts Installation:

- Place batts between purlins without compressing them.

- Use staples or wire to hold them in place.

- Make sure there are no gaps for heat to escape.

- Rigid Foam Boards Installation:

- Cut foam boards to fit snugly between or over purlins.

- Attach securely using adhesive or screws.

- Seal edges with foam tape or spray foam.

- Spray Foam Application:

- Best left to professionals due to specialized equipment and ventilation requirements.

- Spray foam expands to fill gaps and creates an airtight seal.

- Ideal for irregular shapes and hard-to-reach areas.

Pro vs. DIY Comparison

Factor DIY Installation Professional Installation

Cost Saves ~40% Higher upfront cost

Quality Risk of gaps and compression errors. Ensures even coverage and sealing.

Time Longer due to learning curve, Faster and more efficient

Warranty: Usually, none often includes a warranty

Energy Savings Calculations

How much can you actually save? Here’s a simple formula:

Energy Savings = Current Annual Energy Bills × 0.3 (30% reduction with R-30 insulation)

Example:

For a 2000 sq ft metal roof in West Bengal with ₹66,667 annual energy costs:

Savings = ₹66,667 × 0.3 = ₹20,000 per year

This means your insulation investment can pay off in just a few years!

Common Mistakes to Avoid

When insulating your metal roof, watch out for these pitfalls:

- Ignoring Ventilation: Without proper airflow, moisture builds up, leading to mold and rust.

- Choosing the Wrong R-Value: Using insulation that’s too thin or thick for your climate reduces effectiveness.

- Poor Sealing: Gaps and cracks allow heat and moisture to bypass insulation, wasting energy.

Avoid these to ensure your insulation lasts longer and performs better.

Maintenance Tips

Keep your insulation effective by:

- Performing annual inspections for leaks or damage.

- Re-sealing edges and joints as needed.

- Cleaning gutters and roof surfaces to prevent water buildup.

Regular maintenance extends the life of your insulation and roof.

Cost Breakdown

Here’s what you can expect to spend:

- Initial costs: $1 to $4 per square foot, depending on insulation type and labor.

- Return on Investment: Typically 2 to 5 years due to energy bill savings of up to 40%.