Imagine stepping into your backyard patio on a sunny afternoon, only to find it’s too dark and gloomy to enjoy. What if you could transform that space into a bright, inviting oasis filled with natural light? That’s where polycarbonate roof sheeting comes in. If you’re wondering how to install polycarbonate roof sheeting to flood your home with sunlight without spending a fortune, you’re in the right place. This material is a game-changer for homeowners looking to upgrade their roofing affordably.

Polycarbonate roof sheeting is a lightweight, rigid plastic that’s UV-resistant and almost unbreakable. It’s a smart alternative to traditional glass or metal roofs, offering durability and style in one package.

What is Polycarbonate Roof Sheeting and Why Choose It?

Have you ever wished for a roofing material that’s strong yet lets in tons of light? Polycarbonate roof sheeting fits that bill perfectly. It’s a type of plastic sheet made from polycarbonate resin, known for its clarity and toughness. You can find it in two main types: multiwall and solid sheets. Multiwall versions have air pockets inside, like a honeycomb, which add insulation. Solid ones are flat and sleek, great for a modern look.

These sheets come in various thicknesses, usually from 6mm to 25mm. Thicker ones offer more strength for larger spans, while thinner options work well for smaller projects. Colors range from clear for maximum light to bronze-tinted for a bit of shade. When you’re deciding how to install polycarbonate roof sheeting, picking the right type depends on your space—clear for bright patios, tinted for areas that get too much sun.

Now, let’s talk about why you’d choose polycarbonate over other materials. First off, its durability is impressive. This stuff is about 250 times stronger than glass, so it won’t shatter if a branch falls on it or hail pelts down. That means fewer repairs and more peace of mind during storms.

Another big plus is light transmission. Polycarbonate lets in up to 90% of natural sunlight, turning dark corners into vibrant spots. Imagine your kitchen or living room extension bathed in daylight—it’s like adding windows without the hassle. This not only makes your home feel bigger but also reduces the need for artificial lights, saving on energy bills.

Insulation is another key benefit. The multiwall design traps air, helping to keep heat out in summer and warmth in during winter. This thermal property can significantly reduce your cooling costs, especially in warmer climates. Plus, it’s lightweight—typically 1 to 2 kg per square meter—which makes handling and installation a breeze compared to heavy metal or glass.

Ease of DIY is a huge draw. You don’t need a team of pros; with basic tools, you can handle the installation of polycarbonate roof sheeting yourself. It’s flexible, bending to fit curved roofs when needed, and affordable, often cheaper than alternatives.

To see how it stacks up, check out this comparison:

Feature Polycarbonate Glass Metal

Cost per m² $20-50 $50-100 $30-60

Weight (kg/m²) 1-2 10-15 5-10

Light Transmission Up to 90% 80-90% 0%

Lifespan (years) 10-20 20-30 20-40

Impact Resistance Very High Low Medium

As you can see, polycarbonate shines in light and durability while keeping costs down. It’s no wonder it’s popular for patios, carports, and greenhouses. For instance, many homeowners use it to create light-filled extensions that blend indoor and outdoor living. If you’re eyeing the advantages of polycarbonate roofing sheets, think about how it could enhance your daily life—more light means happier plants in a greenhouse or a cozy reading nook under the stars.

What about you? Have you noticed dark spots in your home that could use a boost? Polycarbonate might be the fix. It’s not just practical; it adds a modern aesthetic that boosts your property’s value.

Tools and Materials Needed for Polycarbonate Roof Sheeting Installation

Getting started on how to install polycarbonate roof sheeting means gathering the right tools and materials. Don’t worry—it’s not a massive list, and most items are easy to find at your local hardware store. Let’s break it down so you can prepare without stress.

First, the essential tools. You’ll need these to measure, cut, and secure everything properly:

- Measuring tape and spirit level: For accurate sizing and ensuring everything is straight.

- Drill with bits: To make holes for screws, get a variable-speed one for control.

- Screws with neoprene washers: These prevent leaks and allow for expansion.

- Sealant gun and silicone sealant: For watertight joins.

- Fine-tooth circular saw or jigsaw: To cut sheets without cracking them.

- Safety gear: Gloves, goggles, and a sturdy ladder to keep you protected.

Safety comes first. Always wear goggles when cutting, and use a harness if you’re working high up.

Now, for materials, here’s a checklist to cover your project:

- Polycarbonate sheets: Buy enough to cover your roof area, plus 10-15% extra for overlaps and waste.

- Aluminum closures and profiles: These seal the ends and edges.

- Flashing and ridge capping: For finishing touches around eaves and peaks.

- Foam infill strips: To fill gaps and prevent drafts.

- Thermal breaks or rubber gaskets: These help with expansion and reduce noise.

To figure out quantities, measure your roof’s length and width, then add overlap allowances. For a 10m x 5m roof, you’d need about 55-60 square meters of sheeting.

Costs can vary, but here’s a rough breakdown to budget wisely:

Item Estimated Cost per Unit Total for Average Project (50m²)

Polycarbonate Sheets $20-50/m² $1,000-2,500

Screws and Sealants $0.50 each / $10 tube $100-200

Tools (if buying new) $50-200 total $50-200

Safety Gear $20-50 $20-50

Total – $1,170-3,000

Pro tip: Shop from trusted brands to ensure quality—cheap sheets might yellow over time. With these in hand, you’re set for a smooth install of polycarbonate roofing panels step by step. How does your shopping list look? Double-check to avoid mid-project runs to the store.

Preparation: Planning Your Polycarbonate Roof Installation

Before you dive into how to install polycarbonate roof sheeting, preparation is key. It’s like mapping out a road trip—you want to avoid detours. Start by assessing your roof. Check the pitch; it should be at least 5 degrees to allow water to run off. Anything flatter might lead to pooling, so consider adding slope if needed.

Measure the area carefully. Grab your tape and sketch a layout, noting dimensions and any obstacles, such as chimneys. This helps you calculate materials accurately. Don’t forget to check if your existing structure is strong enough—polycarbonate is light, but it still needs solid support.

Next, look into local building codes. Some areas require permits for roof changes, especially for significant additions. A quick call to your local authority can save headaches later. While you’re at it, peek at the weather forecast. Pick a dry, mild day for installation—rain or wind can make things tricky.

Safety is non-negotiable. Set up your ladder on stable ground, and consider a harness for heights over 2 meters. Work with a partner; an extra pair of hands makes lifting sheets easier. Have you thought about your setup? Imagine steadying a ladder alone—better safe than sorry.

Common mistakes? Undersizing purlins (support beams) or omitting expansion gaps. Polycarbonate expands in heat, so leave 3-5mm spaces around screws. Also, ensure your framing is level; wonky supports lead to uneven roofs.

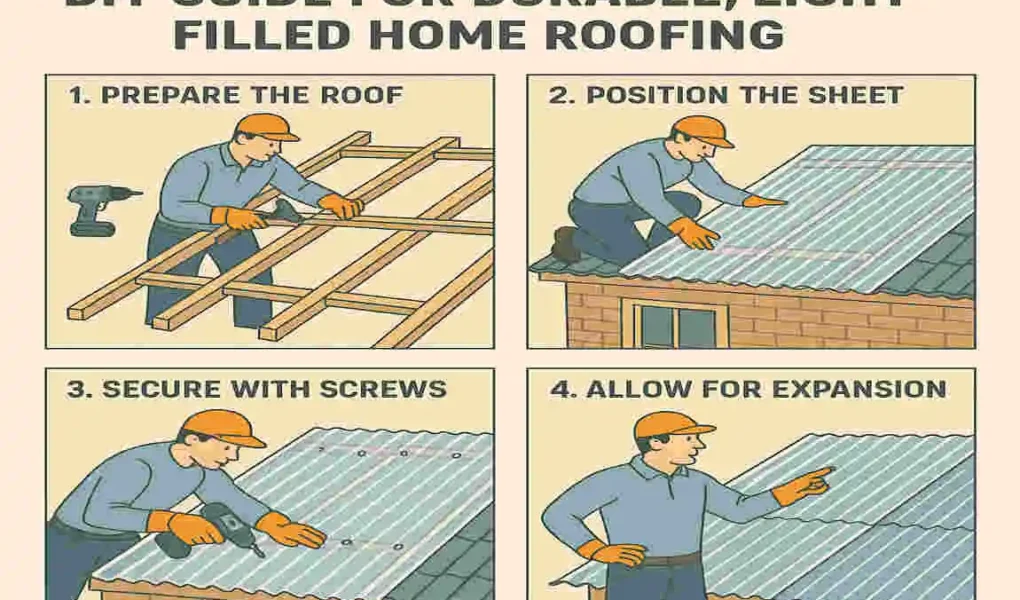

Step-by-Step Guide: How to install Polycarbonate Roof Sheeting

This is the heart of our guide on how to install polycarbonate roof sheeting. We’ll break it down into clear steps, so even beginners can follow along. Remember, take your time—rushing leads to errors. Let’s get your roof light-filled and durable.

install Roof Purlins and Framing

Start with a strong foundation. Purlins are the horizontal beams that support your sheets. Use treated timber or metal for longevity; timber is cheaper and easier for DIYers to work with.

Space them 600-900mm apart, depending on sheet thickness—closer for thinner ones. Secure them to your existing rafters with screws or brackets. Make sure everything is level; use your spirit level here.

Why does spacing matter? Too far apart, and sheets might sag under snow or wind. Aim for even distribution. If you’re building from scratch, add cross-bracing for extra stability.

Cut and Prepare Polycarbonate Sheets

With framing ready, prepare your sheets. Keep the protective film on until the end—it shields against scratches. Measure twice, cut once: Mark lines with a pencil, allowing 10-15% overlap lengthwise and 50mm on sides.

Use a fine-tooth saw at low speed to avoid melting the plastic. Clamp the sheet to a stable surface for clean cuts. For curves, a jigsaw works best.

Handle sheets gently; they’re tough but can scratch. If you’re tinting or adding coatings, do it now—UV protection extends lifespan.

Expansion is crucial: Cut holes slightly larger than screws. This prevents cracking as temperatures change. You’ve got this—precise prep makes fixing easier.

Position and Fix the First Sheet

Begin at the eaves (bottom edge) for proper water flow. Lift the first sheet into place—get help if it’s large. Align it with the purlins, ensuring a 50mm overhang for gutters.

Drill pilot holes oversized (e.g., 10mm for 8mm screws) to allow movement. Insert screws with neoprene washers every 300-500mm along purlins. Don’t overtighten; snug is enough.

Use thermal breaks under screws to reduce heat transfer and noise. Secure the edges first, then the middle. Step back and check alignment—adjust if needed.

This first sheet is your template; get it right, and the rest follow suit. Feeling excited? Natural light is just steps away.

install Subsequent Sheets and Closures

Overlap the next sheet over the first by 150-200mm. Apply silicone sealant along the overlap for a watertight seal. Fix it the same way: drill, screw, secure.

Add foam profiles or closures at ends to block debris and insects. For ridges, install capping that matches your sheet color, and screw it down firmly.

Work row by row, checking for level each time. If sheets don’t align, trim slightly. Sealing is key here; gaps invite leaks.

Windy areas? Add extra fixings. This step builds your roof layer by layer. You’re creating something beautiful and functional—keep going!

Secure Edges, Gutters, and Final Fixes

Focus on edges now: Eaves, hips, and valleys need flashing to direct water. Bend flashing to fit and screw it over the sheet edges.

Integrate gutters by ensuring sheets overhang properly—about 50mm into the gutter. Use clips or brackets for secure attachment.

For wind resistance, add tension clips along perimeters. These hold sheets tight during storms. Go around the roof and tighten any loose screws.

This final securing ensures longevity. Imagine rain bouncing off without a single drip inside—that’s your goal.

Cleaning and Inspection

Almost done! Peel off the protective film carefully—do it slowly to avoid static—then clean the sheets with mild soap and a soft cloth; no harsh chemicals.

Inspect every join, screw, and seal. Look for gaps or misalignments—fix them with extra sealant—test by hosing down to check for leaks.

If all’s good, step back and admire. Your install polycarbonate roofing panels step by step is complete. How does it feel to have more light streaming in?

Maintenance and Troubleshooting for Long-Lasting Polycarbonate Roofing

Once installed, polycarbonate roofs are low-maintenance, but a little care goes a long way. Clean annually with a soft brush and soapy water to remove dirt and algae. Avoid pressure washers—they can scratch the surface.

Common issues? Condensation in multiwall sheets—opt for anti-drip coatings during install to minimize it. Cracks are rare, but if one appears, patch with compatible sealant and tape.

Yellowing from UV? Choose sheets with built-in protection for a 10-20-year lifespan. In high-wind areas, check fixings yearly—Troubleshoot leaks by resealing overlaps.

Regular checks keep your roof performing. You’ve invested time; maintain it to enjoy the benefits of polycarbonate roofing sheets for years.

Cost Analysis: Is DIY Polycarbonate Roof Installation Worth It?

DIY how to install polycarbonate roof sheeting saves big. Materials for a 50m² roof might cost $1,000-2,500, and tools another $100-300. Professional installs add $1,500-3,000 in labor, so you save 50-70%.

ROI shines through energy savings—natural light cuts lighting costs by 20-30%. Plus, increased home value. Worth it? Absolutely, if you enjoy hands-on projects.