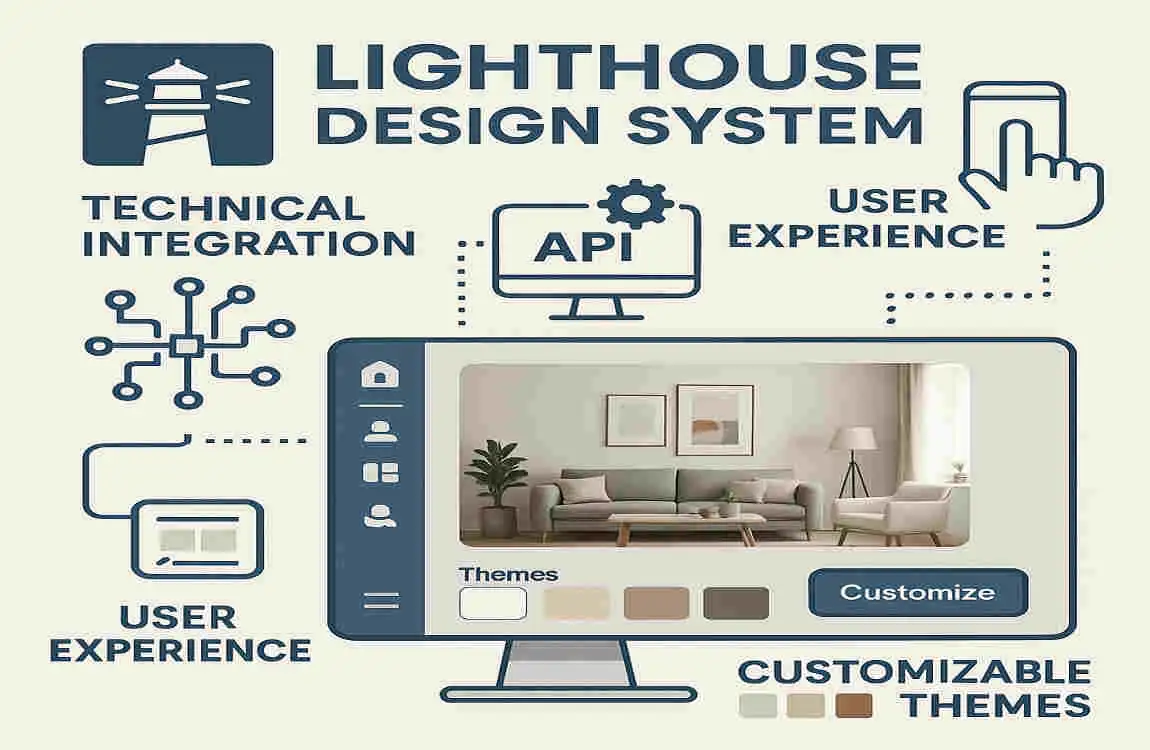

In today’s fast-paced world, where technology influences every aspect of our lives, interior design has undergone a remarkable transformation. The Lighthouse Design System stands out as a groundbreaking tool that revolutionizes collaboration between designers and developers, enabling seamless workflows and delivering personalized, innovative home interiors.

What is the Lighthouse Design System?

The Lighthouse Design System is a cutting-edge solution that seamlessly integrates design and development workflows. It’s not just a design tool—it’s a comprehensive ecosystem that bridges the gap between creative designers and technical developers, ensuring that every element is perfectly aligned with the client’s vision.

Why is Seamless Integration Important?

In traditional interior design projects, there’s often a disconnect between conceptual designs and their real-world implementation. This can result in misaligned expectations, delays, and increased costs. Lighthouse eliminates these hurdles by automating key processes and enabling real-time collaboration, ensuring that designs move from concept to completion efficiently and accurately.

The Role of Customization

Customization is at the heart of modern home design. Clients no longer want cookie-cutter solutions; they demand spaces that reflect their unique personalities and lifestyles. Lighthouse empowers designers with flexible, customizable themes, allowing them to tailor every detail to meet client preferences while maintaining functionality and aesthetic appeal.

Understanding the Core Features of Lighthouse Design System

The Lighthouse Design System introduces a host of innovative features that set it apart from traditional interior design tools. These features make it an indispensable asset for professionals looking to streamline their design processes.

Continuous Design: A New Era of Interior Design

Continuous design is an ongoing, iterative process in which designs evolve fluidly within a single system. Unlike traditional methods that rely on static drafts and multiple iterations, Lighthouse ensures that every change made in the design phase is automatically reflected in the development phase. This end-to-end synchronization saves time and minimizes errors.

Direct Import of Coded Components

One of Lighthouse’s standout capabilities is its ability to import coded components directly. This feature bridges the gap between design and development teams, ensuring the final product aligns with the original vision. Designers can work with exact layouts and measurements that developers can implement without further modifications.

Fully Customizable Themes

Customization is undoubtedly one of Lighthouse’s strongest selling points. Its themes are not only visually appealing but also highly adaptable to various styles, preferences, and functional needs. Whether you’re designing a minimalist living room or a rustic kitchen, Lighthouse provides the tools to create a space that feels uniquely personal.

Customizable Themes: Personalization Meets Functionality

One of the most exciting aspects of the Lighthouse Design System is its focus on customizable themes. These themes empower designers to create spaces that are not only visually stunning but also tailored to their clients’ specific needs and preferences.

Catering to Diverse Tastes and Styles

Every client is unique, and their home should reflect their individuality. Lighthouse offers a wide range of pre-designed themes that can be customized to suit different styles, such as:

- Modern: Sleek lines, neutral tones, and minimalist furniture create a contemporary vibe.

- Rustic: Warm wood textures, earthy colors, and vintage accents evoke a cozy, natural feel.

- Minimalist: Clean spaces with simple furniture, emphasizing functionality.

Each theme serves as a starting point, allowing designers to make adjustments based on the client’s vision.

Enhancing Client Satisfaction and Uniqueness

Customizable themes allow designers to go beyond generic solutions, creating one-of-a-kind spaces that resonate with clients on a personal level. This not only improves client satisfaction but also helps designers stand out in a competitive market.

Practical Applications of Lighthouse in Home Interior Design

Lighthouse isn’t just a concept—it’s a practical tool that can be applied to a variety of interior design projects. Here are some examples of how it can transform home interiors.

Case Study: Modernizing a Family Home

Imagine a family that wants to update their living space to include modern amenities while retaining a warm, welcoming feel. Using Lighthouse, the designer can:

- Choose a modern-rustic theme that blends sleek furniture with natural materials.

- Collaborate with developers to ensure smart home features, such as automated lighting and climate control, are seamlessly integrated.

- Provide real-time updates to the family so they can approve changes as the project evolves.

Integration with Smart Home Technologies

Lighthouse supports the integration of smart home technologies, making it easy to add features such as voice-controlled lighting, energy-efficient appliances, and automated security systems. This adds a layer of functionality that enhances the overall living experience.

Technical Integration and User Experience

For a design system to be effective, it needs to be technically robust and user-friendly. Lighthouse excels in both these areas.

Easy-to-Use Features for Designers and Homeowners

Lighthouse is designed for both professionals and end users. Designers can take advantage of its intuitive interface, while homeowners benefit from the system’s transparency and ease of use.

Compatibility with Popular Tools

Lighthouse is compatible with a wide range of design and development tools, making it easy to incorporate into existing workflows. Whether you’re working with software like AutoCAD or Sketch, Lighthouse ensures seamless integration.

Feature Benefit

Real-Time Collaboration : Faster decision-making and changes

Customizable Themes: Unique designs tailored to clients

Smart Tech Integration: Enhanced functionality and comfort

Why Interior Designers and Homeowners Choose Lighthouse

There’s a reason why Lighthouse is quickly becoming a favorite among design professionals and homeowners alike.

Competitive Advantages

- Efficiency: Projects are completed faster without sacrificing quality.

- Customization: Every space feels personal and unique.

- Sustainability: Lighthouse supports eco-friendly design practices, making it ideal for environmentally conscious clients.

Future Trends: The Evolution of Design Systems in Home Interiors

The future of interior design lies in technology-driven solutions like Lighthouse. As design systems become more advanced, we can expect even greater integration with AI, augmented reality, and sustainable practices.

Lighthouse FAQ

What is the Lighthouse Design System?

The Lighthouse Design System is a continuous design platform that integrates design and development workflows. It allows designers to directly import coded components, use precise layouts and measurements, and publish designs efficiently. This system bridges the gap between creative design and technical implementation, ensuring that every project is executed with precision and ease .

How Does Lighthouse Streamline the Interior Design Process?

Lighthouse simplifies the interior design process by offering tools that enable real-time collaboration between designers and developers. Here’s how it works:

- Direct Import of Coded Components: Designers can import pre-coded components directly into their projects, reducing the need for manual coding and ensuring accuracy .

- Exact Layouts and Measurements: The system uses precise measurements, ensuring that designs are implemented exactly as envisioned .

- Customizable Themes: Designers can choose from a variety of themes and tailor them to meet client preferences, saving time while maintaining creativity .

- Real-Time Updates: Changes made during the design phase are instantly reflected in the development phase, eliminating delays and miscommunication .

What Are the Key Features of Lighthouse?

The Lighthouse Design System offers several standout features that make it a game-changer for interior design:

- Continuous Design Workflow: Unlike traditional design processes, Lighthouse ensures that designs evolve fluidly, with every change automatically synchronized across the system .

- Customizable Themes: Designers can create unique, personalized spaces by modifying pre-designed themes to suit different styles and preferences .

- Sketch Integration: Lighthouse integrates seamlessly with tools like Sketch, allowing designers to upload and update styles, components, and examples quickly .

- Reusable Frontend Code: Developers can translate designs into reusable frontend code, reducing duplication and maintaining clean, testable code.

What Makes Lighthouse Different from Traditional Design Tools?

Traditional design tools often operate in silos, requiring separate workflows for design and development. Lighthouse, on the other hand, offers a unified platform where designers and developers can collaborate in real time. This eliminates the need for back-and-forth communication and ensures that the final product matches the original vision .

Additionally, Lighthouse’s focus on customization and precision sets it apart. Designers can create highly personalized spaces while maintaining exact measurements and layouts, ensuring that every detail is executed flawlessly .

How Do Customizable Themes Work in Lighthouse?

Customizable themes are one of Lighthouse’s most powerful features. These themes serve as a starting point for designers, offering pre-designed layouts and styles that can be tailored to meet specific client needs. Here’s how they work:

- Choose a Theme: Select from a variety of themes, such as modern, rustic, or minimalist.

- Modify Elements: Adjust colors, textures, furniture placement, and other elements to align with the client’s preferences.

- Preview and Publish: Use Lighthouse’s real-time preview feature to see how the design will look before finalizing it .

This level of customization allows designers to create spaces that are not only functional but also uniquely personal.

Can Lighthouse Be Used for Smart Home Integration?

Yes, Lighthouse supports the integration of smart home technologies, making it an ideal tool for modern interior design projects. Designers can incorporate features like:

- Automated Lighting: Control lighting systems with voice commands or mobile apps.

- Energy-Efficient Appliances: Integrate eco-friendly appliances that reduce energy consumption.

- Smart Security Systems: Add advanced security features like motion sensors and remote monitoring.

By combining smart technology with customizable themes, Lighthouse enables designers to create homes that are both stylish and functional.

Is Lighthouse Compatible with Other Design Tools?

Lighthouse is designed to work seamlessly with popular design and development tools, including Sketch and Flutter. This compatibility ensures that designers can integrate Lighthouse into their existing workflows without any disruptions ,.