Two o’clock in the morning. You wake up to the rhythmic drip-drip-drip of a pipe that has finally decided to give up the ghost under your kitchen sink. You are standing there in your pajamas, staring at a puddle, when you realize you have two choices. You can call an emergency plumber and pay a “midnight premium” that costs more than your car payment, or you can try to fix it yourself.

But here is the catch: you do not own a blowtorch, you have never “sweated” a copper pipe in your life, and the thought of open flames near your wooden cabinets makes you break out in a cold sweat.

What Exactly Are SharkBite Fittings?

Before we get into the “good vs. bad” debate, let’s talk about what these things actually are. SharkBite is a brand name that has become the “Kleenex” of the plumbing world. While there are other brands, SharkBite pioneered the push-to-connect brass fitting that most people recognize today, The Science of Push-to-Connect Technology. At its core, a SharkBite fitting uses a clever mechanical design to hold pipes together. When you slide a pipe into the fitting, a series of stainless steel teeth (the “shark” part of the name) bite down on the pipe and grip it tight.

Inside the fitting, there is also a high-quality O-ring made of EPDM (a type of durable rubber). This O-ring creates a watertight seal against the outside of the pipe. There is no glue, no solder, and no heavy clamping tools required. You just push, and it clicks. A Brief History and Certification The SharkBite brand has been around since 2005 and has quickly become a staple in hardware stores like Home Depot and Lowe’s. These fittings are not just “toys” for amateurs; they are certified for potable water (drinking water) and radiant heating applications under ASSE 1061.

They are designed to work with several types of standard household pipes, including:

- Copper (the traditional gold standard)

- PEX (flexible plastic tubing)

- CPVC (rigid plastic pipe)

- PE-RT and HDPE (specialty plastics)

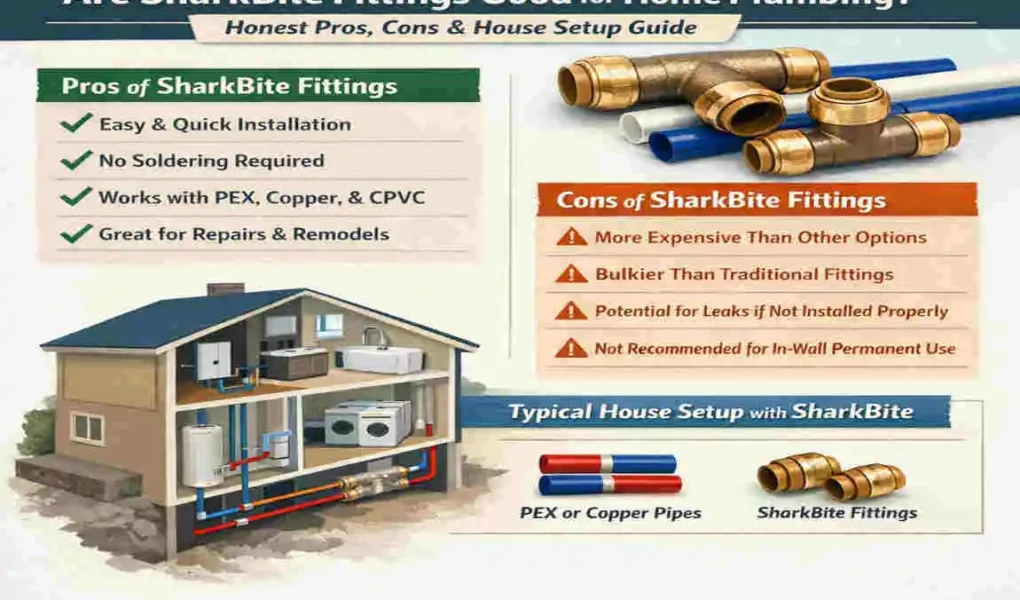

The Major Pros: Why Homeowners Love SharkBite

There is a reason these fittings fly off the shelves despite being more expensive than traditional options. They solve many “pain points” for the average homeowner.

Unmatched Ease of Installation

The biggest “pro” is the speed. You can literally make a connection in 5 to 10 seconds. If you are working in a tight crawlspace or a dark corner under a tub, you don’t want to be fumbling with a torch or a heavy crimping tool. With SharkBite, you just push the pipe in until you feel it seat. It is the ultimate “plug-and-play” for your home’s water lines. Incredible Versatility Across Pipe Materials. Have you ever tried to join a copper pipe to a PEX line? In the old days, that required specific adapters and multiple tools. SharkBite fittings are universal. You can stick a copper pipe in one end, and a PEX pipe in the other, and the fitting doesn’t care. They handle hot and cold water up to 200°F, making them suitable for almost any indoor plumbing task. Safety First: No Torches Required. Soldering (or “sweating”) pipes involves an open flame. If you are working near dry wooden studs or old insulation, one slip can lead to a house fire. SharkBite removes that risk entirely. This makes them a much safer choice for homes with kids, pets, or for anyone who isn’t comfortable playing with fire in a confined space. Reliability When Done Right.

While some old-school plumbers might roll their eyes, SharkBite offers a 25-year warranty when installed correctly. The brass body is sturdy and corrosion-resistant, and the seal is designed to withstand the typical pressure fluctuations of a residential water system. ProBenefit for Homeowners.

Quick Install Saves hours of labor and frustration vs. soldering

Durable Seal Handles high pressure and temperature changes

No Special Tools No need to buy $100+ crimpers or torches

Wet Pipe Friendly : Can be installed even if water is still dripping

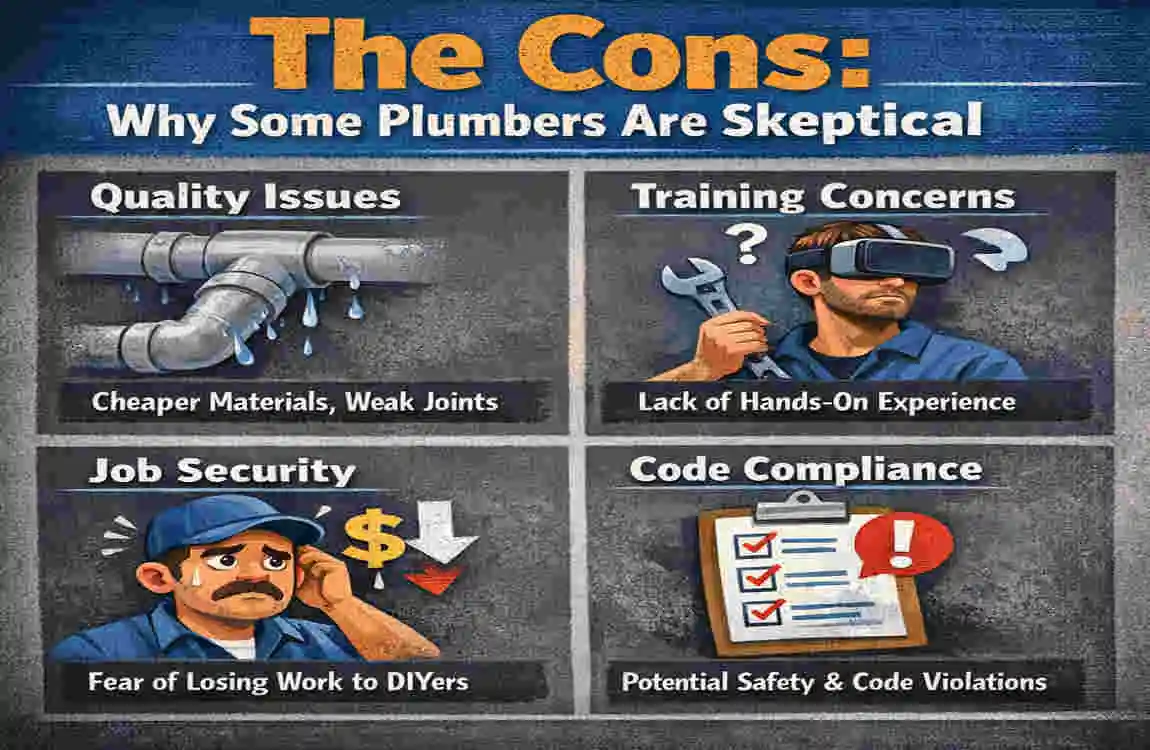

The Cons: Why Some Plumbers Are Skeptical

If Shark Bites are so easy, why doesn’t everyone use them for everything? Well, there are some significant trade-offs you need to consider before you go “all-in” on a whole-house project.

The “Sticker Shock” Factor

This is the most immediate downside. A standard copper “tee” fitting might cost you $1.50. A SharkBite “tee” can cost between $12 and $20. If you are just fixing one leak, that $15 is a bargain compared to a plumber’s visit. But if you are replumbing an entire bathroom with 20 or 30 fittings, that cost adds up to hundreds of extra dollars very quickly. Bulkiness and Space Constraints SharkBite fittings are significantly larger than soldered or crimped fittings. They have a thick brass collar to house the teeth and O-ring. This can be a problem if you are trying to fit pipes into a narrow wall cavity or behind a tight cabinet. Sometimes, they simply won’t fit where a traditional joint would.

Long-Term O-Ring Concerns

The “weak point” of a SharkBite is the rubber O-ring. While they are rated for decades, rubber can eventually degrade, especially if your water has high chlorine levels or if the pipes vibrate a lot (water hammer) Unlike a soldered joint, which becomes a single piece of metal, a SharkBite relies on a mechanical seal that could theoretically fail over a long enough timeline Professional Skepticism and Code Issues Many professional plumbers view SharkBites as a “temporary fix” or an “emergency-only” tool. While they are code-approved in most areas, some local jurisdictions restrict their use behind closed walls where you can’t see if they start to leak. Always check your local building codes before doing a major renovation.

AspectSharkBiteSoldered Copper

Cost per Fitting High ($10-$20) Low ($1-$2)

Longevity 25-year warranty 50+ years

DIY-Friendly Excellent Requires significant skill

Tool Cost Low (just a cutter) Medium (torch, solder, flux)

Are SharkBite Fittings Reliable Long-Term?

The million-dollar question: Will it leak in ten years? The answer is usually no, provided you did the prep work correctly. The fitting itself does not cause most SharkBite failures; it’s poor installation: if you don’t cut the pipe square or leave a sharp burr on the edge of the copper, you can slice the O-ring as you push the pipe in. That tiny nick will eventually turn into a leak However, if the pipe is clean. The fitting is pushed in until it “clicks” or hits the internal stop, they are remarkably stable generally suggest using them in accessible locations—like under a sink or behind a toilet—where you can easily inspect them once a year For pipes buried deep inside a foundation or a tiled shower wall, many pros still prefer the “permanent” nature of a solder or a PEX crimp joint.

Your House Setup Guide: When & How to Use Shark Bite

Ready to try it out? Follow this guide to ensure your first SharkBite repair doesn’t end in a soggy mess.

Assessing Your Setup

Shark Bites are perfect for:

- Fixing a burst pipe in an emergency.

- Connecting a new faucet under a sink and adding a shut-off valve to a toilet line.

- Transitioning between different pipe types (e.g., Copper to PEX).

Avoid using them for:

- Outdoor lines that might freeze and thaw repeatedly. Gas lines (SharkBites are for water only!).

- High-vibration areas (like right next to a heavy-duty pump).

Gathering the Right Tools

You don’t need much, but you do need the right basics:

- Pipe Cutter: A clean, square cut is non-negotiable.

- Deburring Tool: This is the most important tool you’ve never heard of. It smooths the edges of the pipe so they don’t cut the O-ring.

- A Marker: To mark the “depth” so you know the pipe is entirely in.

- Disconnect Clip: A cheap plastic tool that lets you take the fitting off if you make a mistake.

Preparing the Pipe Like a Pro

Cut your pipe as straight as possible. If it’s slanted, the O-ring won’t sit evenly. Use your deburring tool to clean the inside and outside of the pipe. Finally, use a SharkBite depth gauge (or a ruler) to mark the depth the pipe needs to extend into the fitting. For a 1/2″ pipe, this is usually about 1 inch Step 4: Making the Connection Push the fitting onto the pipe firmly. You will feel some resistance as it passes the O-ring. Then a final “thud” as it hits the back of the fitting. Check your mark. If the mark is flush with the fitting, you are golden Give it a firm tug to make sure the “teeth” have grabbed hold.

Home AreaRecommended?Tips

Kitchen Sink Yes Perfect for quick faucet swaps

Bathroom Vanity Yes , great for adding shut-off valves

Main Supply Line Limited Use only for accessible repairs

Outdoor Spigot No Avoid due to pressure and freeze risks

SharkBite vs. The Competition: Which Wins?

If you are looking at a big project, you might be considering other options, such as PEX Crimp or Compression fittings. Here is how they stack up:

- PEX Crimp: This is what most new homes use. It requires a $60- $100 crimping tool, but the fittings are very cheap (under $1 each). It is more reliable than SharkBite for whole-house systems, but it only works with PEX pipe.

- Compression Fittings: These use a nut and a brass ring (ferrule) to squeeze the pipe. They are common for toilet and sink hookups. They are cheaper than SharkBite but can be finicky to get “just right” without over-tightening.

- Soldering: The old-school way. It is the cheapest and most permanent, but it has the steepest learning curve and the highest fire risk.

Fitting Type Cost Ease Durability Best For

SharkBite $$$ Very Easy Good (25y) DIY Repairs

Soldered $ Hard Excellent Pros/Main Lines

PEX Crimp $$ Medium Good New Builds

Compression $$ Medium Fair Temporary Fixes

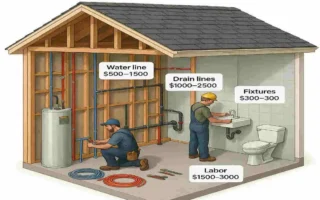

Cost Breakdown: Is the Convenience Worth the Cash?

Let’s talk numbers. If you have a small leak in a copper pipe, a plumber might charge you $150 to $300 just to show up and spend 15 minutes soldering it.

FAQ: Are SharkBite fittings good for plumbing?

Q) Are SharkBite fittings good for home plumbing?

Yes—they’re generally considered reliable for repairs, especially for typical residential situations where you need a fast, solid connection.

Q) Are they “as good as soldering/brazing”?

Most pros would say no—they’re often viewed as very good, but not as strong or “forever” as brazing/soldered joints for certain critical applications.

Q) When do they make the most sense?

They’re especially useful when you can’t easily shut off water or you need a quick solution like capping stub-outs or popping on a valve fast.

Q) Why are plumbers sometimes wary of SharkBites?

Because the simplicity can lead to amateur mistakes (like poor pipe prep or not seating the pipe fully), which can cause problems later.

Q) Are SharkBites widely used, or are they just a DIY niche?

They’re widely adopted—SharkBite has been described as making over 1.5 million connections each week, which shows they’re common in real-world use.

Q) Do professionals recommend them?

It’s mixed. Some sources say pros don’t recommend them as a go-to choice, while many tradespeople still admit they’ll use them in a pinch or in their own homes under the right conditions.

Q) Are they expensive compared to other fittings?

Yes—many people point out the cost difference is “outrageous” compared to other systems (like standard PEX fittings), so they’re often best for specific repairs, not whole-house projects.

Q) Are they safe and beginner-friendly?

They can be, because soldering isn’t needed, which avoids torch-related risks and makes the job more accessible for homeowners.

Q) Should you hang heavy items (like an expansion tank) from a SharkBite connection?

Most advice says don’t rely on the fitting to support weight—the connection can be watertight, but you should strap/support heavy loads separately.

Q) What’s the bottom-line rule for using them at home?

Use SharkBites for quick, convenient repairs—but be extra careful with installation and think twice for mission-critical or hard-to-access locations, since misuse and long-term risk are the common concerns people raise.