Have you ever wondered how much lumber is needed to build a house? Whether you are planning to build your dream home or simply curious about construction logistics, understanding lumber requirements is essential. It is not just about having enough wood to complete the project—it is about thoughtful planning that saves money, time, and resources.

Think about it this way: lumber typically accounts for a significant portion of your construction budget. Getting the quantities right from the start means you will not face costly delays from material shortages or waste money on excess materials that gather dust. Plus, with today’s fluctuating lumber prices, accurate planning has never been more crucial.

Understanding Lumber Basics

Before we calculate how much lumber is needed to build a house, let us get familiar with the building blocks of home construction. Understanding lumber types and measurements will make everything else fall into place.

Types of Lumber in House Construction

Framing lumber forms the skeleton of your home. These are typically 2x4s, 2x6s, 2x8s, and larger dimensional lumber used for walls, floors, and roof structures. They bear the weight and provide structural integrity.

Sheathing materials like plywood and OSB (oriented strand board) cover the frame. These large sheets create the surfaces for your walls, floors, and roof before the final finishes go on.

Trim lumber adds those finishing touches. Think baseboards, crown molding, and window casings. While not structural, trim lumber significantly impacts your home’s final appearance and can add up in quantity.

Standard Lumber Dimensions and Measurements

Here is something that confuses many first-time builders: a 2×4 does not actually measure 2 inches by 4 inches! Due to milling and drying processes, it is actually 1.5 inches by 3.5 inches. This applies to all dimensional lumber—the nominal size differs from the actual size.

Lumber gets measured in several ways:

- Board feet: The volume measurement equaling 144 cubic inches

- Linear feet: Simply the length of the board

- Square feet: Used for sheet goods like plywood

Understanding these measurements helps you communicate effectively with suppliers and ensures accurate ordering.

Lumber Grades and Quality

Not all lumber is created equal. Structural grades range from Select Structural (the highest) down to Utility grade. For house framing, you will typically use construction-grade or better.

The grade affects both strength and appearance. While you might save money with lower grades, they could have more knots, warping, or other defects that complicate construction. For critical structural elements, never compromise on quality—it is your family’s safety at stake.

Factors Affecting Lumber Quantity

Now that we understand lumber basics, let us explore what determines how much lumber is needed to build a house. Several key factors come into play, and understanding them helps you plan more accurately.

House Size and Square Footage

The most apparent factor is size. A 3,000 square foot home naturally requires more lumber than a 1,500 square foot cottage. However, here is the thing—it is not a simple linear relationship.

Larger homes often have more efficient material usage per square foot. Why? Because certain elements, like exterior walls, do not increase proportionally with floor area. A rectangular 2,000 square foot home might have less exterior wall length than a complex 1,800 square foot design with multiple wings and angles.

Structural Design Complexity

Single-story versus multi-story homes present different lumber needs. Two-story homes require stronger first-floor framing to support the upper level, meaning larger joists and possibly doubled-up studs. However, they often use lumber more efficiently overall since they have less roof area relative to living space.

You may also read (what factors determine the cost to build a house in houston).

The roof design dramatically impacts lumber quantities, too. A simple gable roof uses far less lumber than a complex hip roof with multiple valleys and dormers. Each intersection and angle requires additional framing members and creates more waste from angle cuts.

Architectural Features and Details

Those beautiful architectural details you love? They come with a lumber cost. Bay windows require exceptional framing and additional materials. Vaulted ceilings need more extended rafters and sometimes engineered lumber products. Covered porches and attached garages add significantly to your lumber tally.

Even seemingly minor features add up. A bump-out for a breakfast nook, an angled wall in the main bedroom, or decorative ceiling beams all increase complexity and material needs.

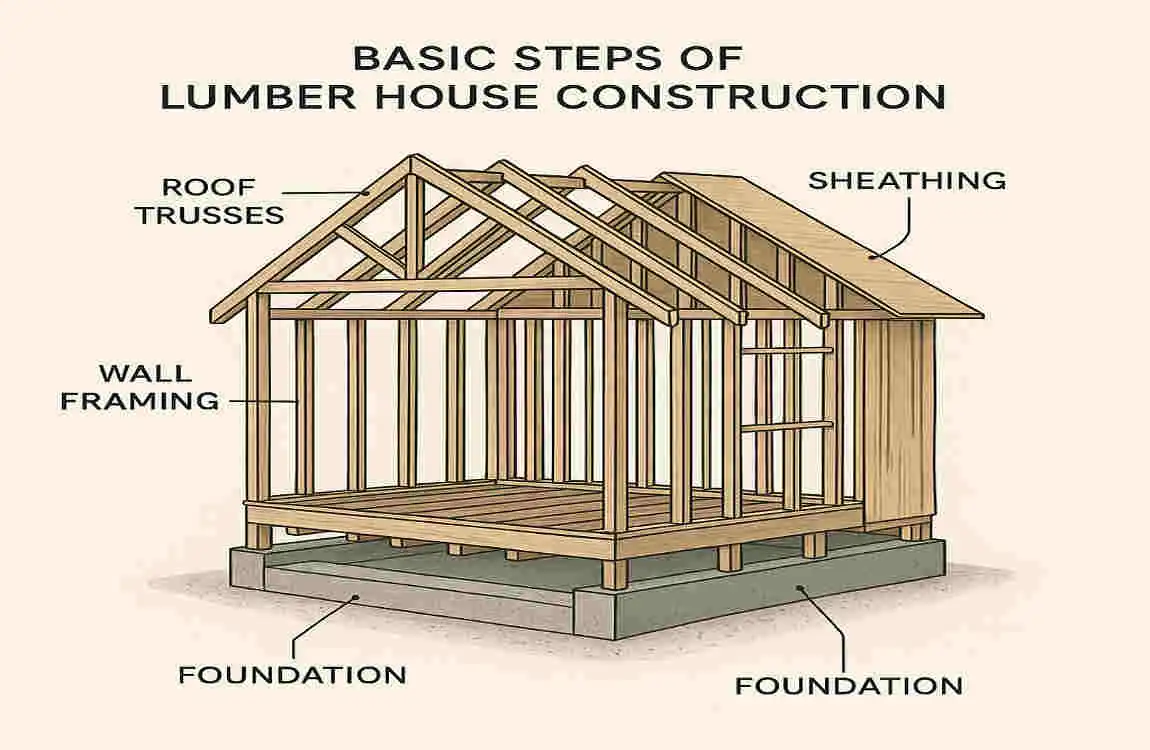

Foundation and Framing Methods

Your foundation type influences lumber requirements from the ground up. Slab foundations need less lumber than crawl spaces or full basements, which require floor joists and subflooring for the main level.

Platform framing—today’s standard method—builds one story at a time, making it easier to construct but potentially using more lumber at connection points. Balloon framing, though rare now, runs studs continuously from foundation to roof, using longer lumber pieces but potentially less total material.

Regional Codes and Climate Considerations

Where you build matters tremendously; hurricane-prone areas require additional bracing, tie-downs, and sometimes larger framing members. Snow country demands stronger roof framing to handle heavy loads. Seismic zones need special connections and shear walls.

Local building codes reflect these regional needs. What passes inspection in temperate Georgia might fall short in earthquake-prone California or snow-heavy Minnesota. Always factor in these regional requirements when calculating lumber needs.

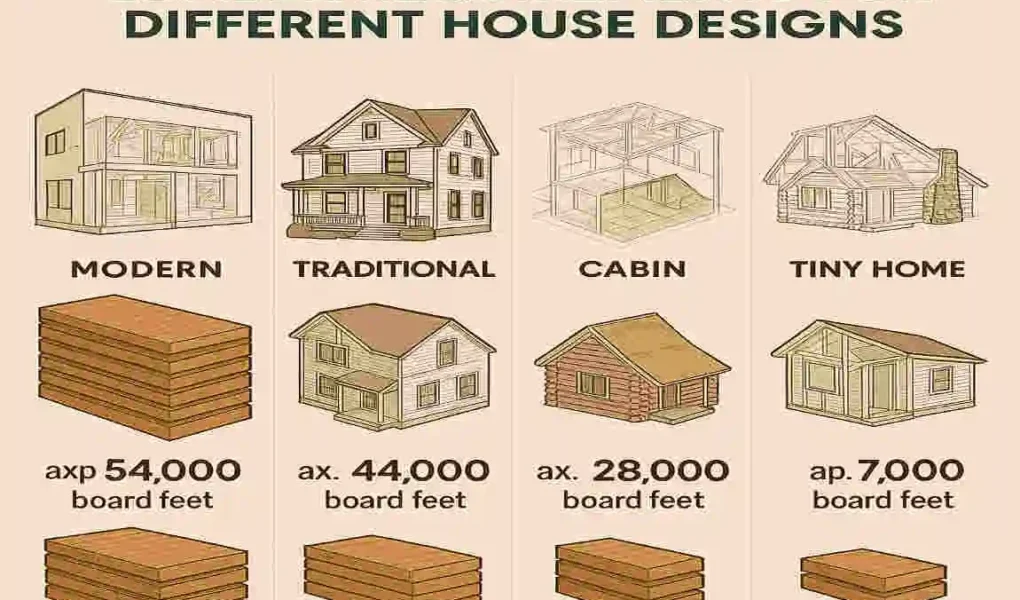

Lumber Requirements for Different House Designs

Let us get specific about how much lumber is needed to build a house based on popular design styles. Each architectural approach has unique characteristics that affect material usage.

Ranch-Style Houses

Ranch homes, with their single-story sprawl, are lumber workhorses. A typical 1,800 square foot ranch might require:

- 6,000-8,000 board feet of framing lumber

- 80-100 sheets of plywood/OSB sheathing

- 3,000-4,000 linear feet of various dimensional lumber

The extended, low profile means extensive roof framing. Without a second story to break up the span, ranch homes often need larger ceiling joists or trusses. The spread-out design also means more exterior wall surface, increasing both framing and sheathing needs.

However, ranch homes offer construction simplicity. No stairs to frame, no complex load transfers between floors, and easier access during construction can reduce waste and improve material efficiency.

Two-Story Houses

Two-story designs use vertical space efficiently, often requiring less total lumber per square foot of living space. A 2,400 square foot two-story home typically needs:

- 8,000-10,000 board feet of framing lumber

- 100-120 sheets of sheathing

- 4,000-5,000 linear feet of dimensional lumber

The key advantage? A smaller footprint means less foundation and roof area. The main lumber intensity comes from floor framing between stories and the need for larger first-floor studs or posts to carry upper-level loads.

Stairway framing adds complexity and material needs. A typical straight staircase requires specialized framing and can consume 200-300 board feet of lumber just for the structure.

Cottage and Bungalow Designs

These charming designs often feature complex rooflines and architectural details that boost lumber requirements. A 1,500 square foot cottage might need:

- 5,500-7,500 board feet of framing lumber

- 70-90 sheets of sheathing

- 3,500-4,500 linear feet of trim and detail lumber

Dormers, covered porches, and decorative gables are cottage hallmarks that add character—and lumber. Each dormer can add 200-400 board feet to your total. Wraparound porches might require another 1,000-2,000 board feet, depending on size and design.

The traditional steep-pitched roofs of cottages use more rafter material than low-slope ranch roofs. However, this can be offset by using manufactured trusses, which optimize lumber usage through engineering.

Modern and Custom Architectural Homes

Contemporary designs with their open floor plans, large windows, and unique geometries present special challenges. Lumber needs vary wildly, but expect:

- 20-40% more framing lumber than traditional designs

- Engineered lumber products for long spans

- Additional specialty materials for unique features

Open-concept living means longer spans, requiring engineered beams or larger dimensional lumber. Floor joists might jump from 2x10s to 2x12s or even engineered I-joists. Those stunning floor-to-ceiling windows? They need hefty headers and sometimes steel reinforcement.

Flat or low-slope roofs standard in modern designs might use less lumber than traditional pitched roofs, but they require beefier structural members to handle snow loads without the help of steep slopes.

Tiny Homes and Small Cottages

Do not let the size fool you—tiny homes can be lumber-intensive per square foot. A 400 square foot tiny house might need:

- 2,000-3,000 board feet of framing lumber

- 25-35 sheets of sheathing

- 1,500-2,000 linear feet of various lumber

Why so much for such a small space? Efficiency challenges. You still need corners, doors, windows, and all the structural elements of a larger home, just compressed. The lumber-to-living-space ratio is actually higher than in conventional homes.

Many tiny homes are built on trailers, requiring additional floor framing strength. Mobile tiny homes require additional bracing and connection hardware, further increasing material requirements.

How to Calculate Lumber Needed for a House Build

Ready to figure out how much lumber is needed to build a house? Let us walk through the calculation process step by step. Do not worry—it is more straightforward than you might think!

Step-by-Step Calculation Guide

Start with your house plans. Detailed blueprints are essential. Look for framing plans that show every stud, joist, and rafter. If you only have floor plans, you will need to work with a professional to develop framing details.

Calculate wall framing. Count studs for each wall, typically spaced 16 inches on center. Do not forget corners (usually three studs), door openings (king studs, jack studs, headers), and window framing. Add 10-15% for waste and mistakes.

Figure floor framing. Measure joist runs and count based on spacing (usually 16 or 24 inches on center). Include rim joists, blocking, and any exceptional framing for stairs or openings. Different rooms might need different joist sizes.

Determine roof framing needs. Whether using rafters or trusses, calculate based on your roof’s span and pitch. Steep roofs need longer rafters. Complex roofs with valleys and hips need additional specialty cuts.

Add sheathing requirements. Calculate wall, floor, and roof areas in square feet, then divide by 32 (standard 4×8 sheet). Add 10% for waste, more for complex designs.

Understanding Board Feet Calculations

The board foot confuses many people, but it is simple once you understand it. One board foot equals 144 cubic inches of wood. Here is the formula:

Board Feet = (Thickness in inches × Width in inches × Length in feet) ÷ 12

For example, a 2×6 that’s 10 feet long:

- 2 × 6 × 10 ÷ 12 = 10 board feet

However, remember—use actual dimensions! That 2×6 is really 1.5 × 5.5 inches, so:

- 1.5 × 5.5 × 10 ÷ 12 = 6.875 board feet

Using Plans and Elevations

Your building plans are goldmines of information. Elevation drawings show wall heights and roof pitches. Section drawings reveal hidden framing like headers and floor systems. Detailed drawings explain complex connections requiring extra lumber.

Create a systematic approach:

- List each room or area

- Note all framing members needed

- Record dimensions and quantities

- Calculate board feet for each type

- Sum everything up

Online Tools and Calculators

Technology makes calculating easier. Several excellent online calculators can help estimate how much lumber is needed to build a house:

- Basic framing calculators handle standard wall and floor framing

- Advanced calculators include factors like waste percentages and regional variations

- Supplier tools often provide estimates based on their specific products

However, treat these as starting points. Every house is unique, and calculators cannot account for all variables. They are great for ballpark figures and reality checks on your manual calculations.

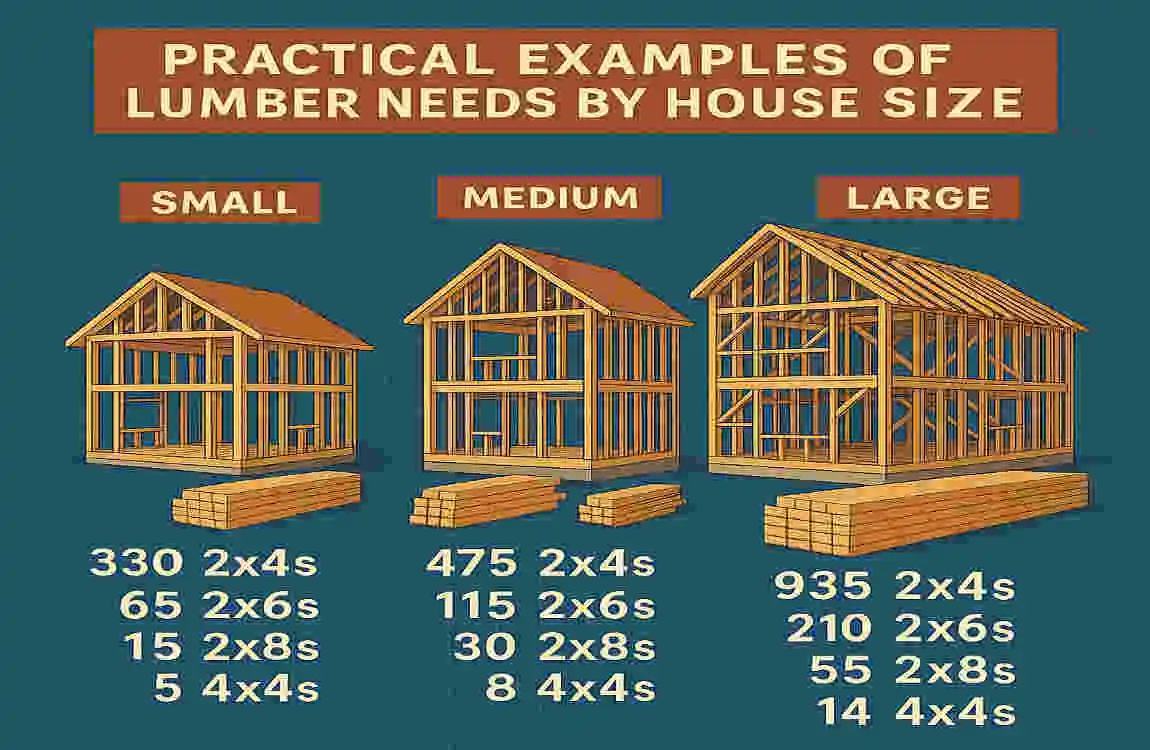

Practical Examples of Lumber Needs by House Size

Let us put theory into practice with real-world examples showing how much lumber is needed to build a house of different sizes. These detailed breakdowns will help you visualize actual material requirements.

Example 1: 1,200 Square Foot Single-Story House

Picture a cozy three-bedroom ranch with an attached two-car garage. Here is the lumber breakdown:

Framing Lumber:

- Wall studs (2×4 and 2×6): 2,800 board feet

- Floor joists (2×10): 1,200 board feet

- Ceiling joists (2×8): 900 board feet

- Rafters (2×10): 1,100 board feet

- Headers and specialty framing: 400 board feet

- Total framing: 6,400 board feet

Sheathing Materials:

- Wall sheathing: 45 sheets

- Roof sheathing: 38 sheets

- Floor sheathing: 38 sheets

- Total sheathing: 121 sheets

Additional Materials:

- Trim and finish lumber: 800 linear feet

- Blocking and miscellaneous: 300 board feet

Estimated total cost at current prices: $18,000-$25,000 (varies by region and lumber prices)

Example 2: 2,500 Square Foot Two-Story House

Now let us scale up to a four-bedroom colonial with more complex features:

Framing Lumber:

- First-floor walls (2×6): 2,200 board feet

- Second-floor walls (2×4): 1,800 board feet

- First-floor joists (2×12): 1,800 board feet

- Second-floor joists (2×10): 1,600 board feet

- Roof rafters/trusses: 2,400 board feet

- Stairway framing: 300 board feet

- Headers and specialty: 900 board feet

- Total framing: 11,000 board feet

Sheathing Materials:

- Wall sheathing: 78 sheets

- Roof sheathing: 52 sheets

- Floor sheathing: 78 sheets

- Total sheathing: 208 sheets

Additional Materials:

- Trim and finish lumber: 1,400 linear feet

- Deck and porch lumber: 800 board feet

- Blocking and miscellaneous: 500 board feet

Estimated total cost: $32,000-$45,000

Example 3: 800 Square Foot Tiny Home

Small but mighty, this tiny home on a foundation shows interesting proportions:

Framing Lumber:

- Wall studs (2×4): 1,400 board feet

- Floor joists (2×8): 600 board feet

- Roof rafters (2×6): 700 board feet

- Loft framing: 300 board feet

- Headers and specialty: 200 board feet

- Total framing: 3,200 board feet

Sheathing Materials:

- Wall sheathing: 28 sheets

- Roof sheathing: 18 sheets

- Floor sheathing: 25 sheets

- Total sheathing: 71 sheets

Estimated total cost: $9,000-$14,000

Comparing Lumber Efficiency

Here is a fascinating comparison table showing lumber usage efficiency:

House Type Square Feet Board Feet BF per Sq Ft Sheathing Sheets Cost per Sq Ft

Ranch (Ex 1) 1,200 6,400 5.33 121 $15-21

Two-Story (Ex 2) 2,500 11,000 4.40 208 $13-18

Tiny Home (Ex 3) 800 3,200 4.00 71 $11-17

Notice how the two-story home uses lumber most efficiently per square foot? The vertical design pays dividends in material efficiency, while the tiny home’s efficiency stems from its simplified design, despite higher per-square-foot usage.

Tips to Optimize Lumber Use and Reduce Waste

Competent builders know that understanding how much lumber is needed to build a house is only half the battle. The real savings come from using that lumber efficiently. Let us explore proven strategies to stretch your lumber budget further.

Efficient Framing Techniques

Advanced framing (also called Optimum Value Engineering) can reduce lumber use by 20-30% without compromising strength. How? By eliminating redundant framing members and optimizing spacing.

Instead of automatically framing 16 inches on center, consider 24-inch spacing where codes allow. This simple change can eliminate hundreds of studs in a typical home. Use single top plates instead of double where possible, and eliminate unnecessary jack studs by using hangers for headers.

Stack framing aligns floor, wall, and roof framing members vertically. This direct load transfer allows for smaller headers and eliminates some blocking. It is like creating a straight line from roof to foundation—efficient and strong.

Right-sizing headers saves significant lumber. Many builders use oversized headers “just to be safe,” but proper calculation often allows smaller members. A 2×8 header might work where you assumed you needed a 2×12.

Smart Purchasing Strategies

Buy in bundles rather than individual pieces when possible. Lumber yards often discount bundled materials, and you will get more consistent quality. Plus, bundles are easier to protect from the weather during construction.

Consider pre-cut packages for common framing elements. Some suppliers offer pre-cut stud packages that eliminate waste from cutting standard lengths. While slightly more expensive per piece, the labor savings and waste reduction often make it worthwhile.

Time your purchases strategically. Lumber prices fluctuate seasonally and with market conditions. If possible, consider buying during traditionally slower construction periods to secure better prices. Lock in prices early if you see favorable rates.

Reusing and Recycling Lumber

Create a cut list station on-site where all drops and cutoffs get sorted by size. That 3-foot piece of 2×10 from a joist might be perfect for blocking or a header component. Organization is key—random piles become waste, but sorted materials get reused.

Plan for common uses of cutoffs:

- Short 2×4 pieces: blocking, backing for fixtures

- Plywood scraps: gussets, temporary bracing

- Longer drops: cripple studs, temporary railings

Design with standard lengths in mind. Suppose lumber comes in 8, 10, 12, and 16-foot lengths; design rooms and openings to use these efficiently. A 15-foot 6-inch room creates waste; a 16-foot room does not.

Prefab and Modular Components

Engineered lumber products often use wood more efficiently than solid lumber. I-joists, for example, use less wood to span the same distance as solid joists. They are straighter, more consistent, and create less waste from culling twisted pieces.

Pre-manufactured trusses typically use 30% less lumber than stick-framed roofs. Computer design optimizes every member, and factory construction eliminates weather damage and site waste. The slightly higher upfront cost often pays for itself through material and labor savings.

Panelized wall systems take efficiency further. Walls built in controlled environments have almost zero waste, arrive ready to install, and reduce on-site labor. While not suitable for every project, they are worth considering for repetitive designs.

Cost Considerations in Lumber Buying

Understanding how much lumber is needed to build a house directly impacts your budget. Let us dive into the financial side of lumber purchasing and how to make smart money decisions.

Current Market Dynamics

Lumber prices can swing dramatically—sometimes doubling or halving within months. Several factors drive these fluctuations:

Supply chain issues affect availability and pricing. Mill capacity, transportation costs, and import tariffs all play roles. A sawmill fire in British Columbia can impact prices at your local lumber yard.

Seasonal demand creates predictable patterns. Spring and summer see the highest demand as construction ramps up. Winter often brings lower prices but also weather-related delivery challenges.

Economic indicators , such as housing starts and interest rates, influence lumber futures. When new construction booms, prices typically follow. Conversely, economic slowdowns can create buying opportunities.

Budgeting Strategies by House Design

Different house designs impact your lumber budget in various ways:

Simple rectangular designs maximize buying power. Fewer angles mean less waste and more efficient use of standard lengths. A basic ranch might achieve 85-90% material utilization.

Complex architectural designs require budget padding. Those beautiful angles and unique features typically mean 70-75% utilization. Budget an extra 20-30% for waste and specialty cuts.

Two-story designs offer budget advantages through efficiency. While requiring stronger first-floor framing, the reduced foundation and roof area often result in lower overall material costs per square foot.

Breaking Down the Budget

Here is how lumber costs typically distribute in a house build:

- Framing lumber: 35-40% of total lumber budget

- Sheathing materials: 25-30%

- Floor systems: 15-20%

- Roof framing: 10-15%

- Trim and finish: 5-10%

Pro tip: Create separate budget lines for each category. This helps identify where costs increase and where you might find opportunities for savings.

Cost-Saving Opportunities

Volume discounts kick in at certain thresholds. Buying all lumber from one supplier often yields 5-10% savings versus piecemeal purchasing. Some yards offer contractor accounts with additional discounts.

Grade optimization balances quality and cost. Use higher grades only where necessary—utility grade works fine for temporary bracing and hidden blocking. Save premium grades for visible applications.

Alternative species can offer savings. While Douglas fir might be traditional in your area, southern yellow pine or hem-fir might provide equal performance at lower cost. Check local codes and span tables to ensure compliance.

You may also read (what materials are used to build a lighthouse).