Choosing the right type of house construction is one of the most critical decisions you’ll make when building your dream home. It’s not just about picking materials or following trends – it’s about creating a living space that will serve you well for decades to come.

Think about it for a moment. The construction method you choose today will determine your home’s energy bills, maintenance needs, and even its ability to withstand natural disasters. It affects everything from your carbon footprint to your family’s comfort and safety.

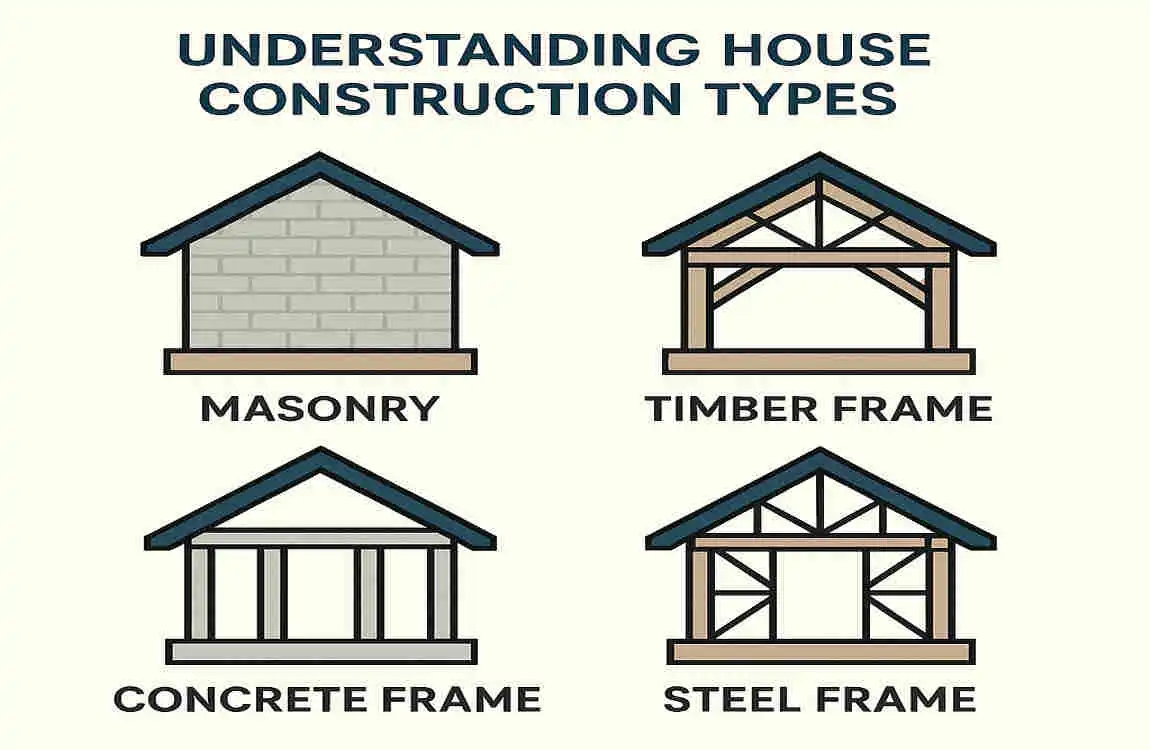

Understanding House Construction Types

When you’re standing at the crossroads of choosing a construction method, it helps to understand what’s actually available in today’s market. The construction industry has evolved dramatically over the past few decades, offering more options than ever before.

Let’s start with the basics. House construction types refer to the fundamental methods and materials used to build the structural framework of your home. Each type brings its own set of characteristics, advantages, and considerations to the table.

Traditional construction remains popular for good reason. This method involves building homes stick by stick, using conventional materials like wood, brick, and concrete blocks. Contractors work on-site, constructing everything from the ground up. It’s flexible and familiar, but it can be time-consuming and weather-dependent.

Modular construction takes a different approach entirely. Imagine building blocks for adults – entire sections of your home are manufactured in a controlled factory environment. These modules are then transported to your site and assembled like a sophisticated puzzle. The precision is remarkable, and quality control is exceptional.

Prefabricated homes share similarities with modular construction but typically involve panels rather than complete modules. Wall sections, roof trusses, and floor systems arrive ready to install. It’s like having a giant kit with all the pieces pre-cut and prepared.

Concrete construction offers unmatched strength and durability. Whether poured on-site or using precast elements, concrete homes can withstand almost anything nature throws at them. They’re particularly popular in areas prone to hurricanes or earthquakes.

Steel frame construction brings commercial building techniques to residential projects. The skeleton of your home consists of steel beams and columns, providing incredible strength while allowing for open floor plans and creative designs.

Timber frame construction combines traditional craftsmanship with modern engineering. Heavy wooden posts and beams create the structure, often left exposed for aesthetic appeal. It’s a method that connects us to centuries of building tradition while incorporating contemporary improvements.

Why does your choice of construction type matter so much? Simply put, it affects every aspect of your homeownership experience. Your construction method influences initial costs, ongoing maintenance, energy efficiency, insurance rates, and even your home’s resale value.

Criteria for Choosing the Best House Construction

Making an informed decision about house construction requires carefully evaluating multiple criteria. Let’s break down the essential factors that should guide your choice.

Sustainability: Building for Tomorrow

Environmental responsibility has moved from being a nice-to-have to an absolute necessity. When evaluating construction methods, consider how they impact our planet. This includes everything from the sourcing of raw materials to the energy required for manufacturing and transportation.

Eco-friendly construction goes beyond the use of recycled materials. It encompasses the entire lifecycle of your home. How much energy will it consume for heating and cooling? What’s the carbon footprint of production? Can materials be recycled or repurposed at the end of their life?

Energy efficiency plays a crucial role here. Some construction types naturally provide better insulation, reducing your reliance on artificial heating and cooling. This not only saves money on utility bills but also reduces your environmental impact year after year.

Speed of Construction: Time is Money

The timeline of your project can make or break your budget and plans. Weather delays, labor shortages, and material availability all significantly affect traditional construction methods.

Modern construction techniques can dramatically reduce build times. Some methods allow for simultaneous site preparation and building fabrication. While your foundation is being poured, your walls might be taking shape in a factory miles away.

Technology has revolutionized construction speed. Computer-aided design ensures precision, while automated manufacturing processes eliminate human error and delays. What once took months can now be accomplished in weeks.

Durability: Building to Last

Nobody wants to invest in a home that requires constant repairs. Structural integrity should be a top priority when selecting your construction method. Consider your local climate and environmental challenges.

Different materials respond differently to moisture, temperature fluctuations, and pest pressure. Some construction types excel in wet climates, while others perform better in dry conditions. Understanding these characteristics helps you choose a method that will stand the test of time.

Maintenance requirements vary significantly between construction types. While some methods might cost more initially, they could save thousands in maintenance over the years.

Cost-Effectiveness: Balancing Budget and Value

The true cost of construction extends far beyond the initial price tag. Smart homeowners consider both immediate expenses and long-term financial implications.

Initial investment includes materials, labor, and equipment. However, don’t overlook ongoing costs like energy bills, insurance premiums, and maintenance expenses. A slightly higher upfront investment might yield significant savings over the lifetime of your home.

Aesthetic Flexibility and Customization

Your home should reflect your personality and lifestyle. Different construction methods offer varying degrees of design flexibility. Some allow for easy modifications during construction, while others require decisions to be finalized early in the process.

Consider whether you might want to expand or modify your home in the future. Certain construction types make renovations simpler and more cost-effective than others.

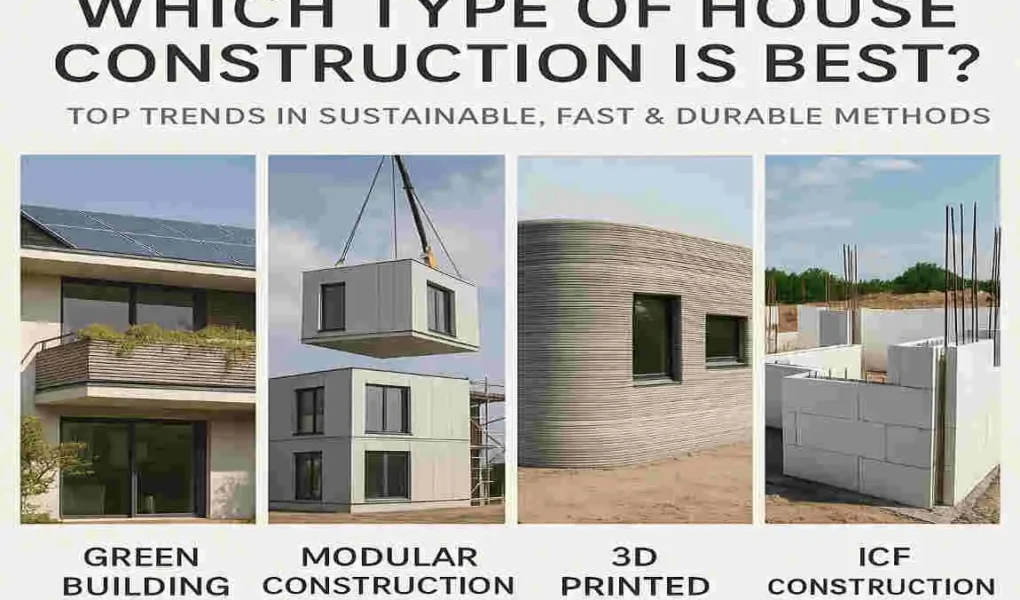

Top Sustainable Construction Methods

Green Building Using SIPs (Structural Insulated Panels)

Structural Insulated Panels represent a revolutionary approach to sustainable construction. These ingenious panels consist of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB).

The beauty of SIPs lies in their simplicity and effectiveness. Each panel arrives at your construction site pre-cut and ready to install. Windows and doors openings are already precisely measured and cut. This precision manufacturing reduces waste to almost nothing—a stark contrast to traditional construction, where material waste can reach 20% or more.

Energy efficiency with SIPs is truly remarkable. Continuous insulation eliminates thermal bridging – those sneaky paths through which heat escapes from your walls. Traditional stud walls have insulation interrupted by wooden frames every 16 inches. SIPs provide an unbroken barrier against heat transfer.

Homeowners using SIPs often report energy savings of 50% or more compared to traditional construction. The airtight building envelope means your heating and cooling systems work less, last longer, and require less maintenance.

Installation speed is another major advantage. A typical home’s shell can be erected in days rather than weeks. This rapid assembly reduces labor costs and minimizes weather-related delays.

Insulated Concrete Forms (ICFs)

ICFs combine the strength of concrete with superior insulation properties. These hollow foam blocks stack like oversized Lego bricks, creating forms that are then filled with reinforced concrete.

The thermal mass of concrete works in harmony with the insulation to create an incredibly stable indoor environment. Your home stays cooler in summer and warmer in winter, with temperature fluctuations measured in degrees rather than the wild swings common in lighter construction.

Disaster resistance is where ICFs truly shine. These structures can withstand hurricane-force winds, earthquakes, and even fire better than almost any other construction method. Insurance companies often offer significant premium reductions for ICF homes.

The environmental footprint deserves consideration. While concrete production does generate CO2, the longevity and energy efficiency of ICF construction offset this initial impact over time. These homes can easily last 100 years or more with minimal maintenance.

Sound insulation is an often-overlooked benefit. The mass of concrete combined with foam insulation creates an incredibly quiet living environment. Outside noise stays outside, and rooms within the home enjoy excellent sound separation.

Passive House Construction Principles

Passive house construction represents the pinnacle of energy-efficient building. This approach doesn’t rely on any single material or method but instead combines multiple strategies to create homes that require minimal heating or cooling.

The core principle is simple yet profound: build an incredibly well-insulated, airtight envelope, then use mechanical ventilation to ensure a steady supply of fresh air. These homes use up to 90% less energy for heating and cooling compared to conventional buildings.

Key elements include super-insulation—walls might be 12 inches or more thick. Triple-glazed windows with insulated frames prevent heat loss. Every potential air leak is meticulously sealed, with special attention paid to electrical outlets, plumbing penetrations, and structural connections.

Heat recovery ventilation systems are the lungs of a passive house. Stale indoor air transfers its heat to incoming fresh air, maintaining comfort while ensuring excellent air quality. You’re essentially recycling the energy you’ve already paid for.

Use of Recycled and Low-Impact Materials

The construction industry is embracing circular economy principles with enthusiasm. Reclaimed wood adds character and history to new homes while helping save trees. Each beam tells a story, whether from an old barn or industrial building.

Recycled steel has become increasingly popular. Steel is infinitely recyclable without losing strength, making it an ideal sustainable choice. Modern steel framing uses a high percentage of recycled content and can be recycled again at the end of its life.

Bamboo deserves special mention as a renewable superstar. Growing faster than any tree, bamboo reaches harvest maturity in just 3-5 years. Its strength rivals steel in tension, and new processing techniques have made it suitable for everything from flooring to structural elements.

Recycled plastic lumber and composite materials turn waste into building resources. These materials resist rot, insects, and weather better than traditional wood while diverting plastic from landfills and oceans.

Fast Construction Techniques for Modern Homes

Modular Homes

The modular home industry has undergone a complete transformation in recent years. Gone are the days of cookie-cutter designs and obvious factory-built aesthetics. Today’s modular homes rival custom-built houses in both quality and appearance.

Factory construction offers incredible advantages. Weather never delays production. Skilled craftspeople work in ideal conditions with professional-grade tools always at hand. Quality control happens at every stage, not just at final inspection.

The speed is breathtaking. While site preparation proceeds, your home takes shape in a climate-controlled facility. Modules typically arrive 60-90% complete, including plumbing, electrical, insulation, and interior finishes. Once modules are set and connected, you could move in within weeks.

Precision manufacturing means less waste and better resource utilization. Computer-controlled cutting ensures every piece fits perfectly. Materials are bought in bulk and stored properly, reducing costs and preventing weather damage.

Prefabricated Panel Systems

Prefabricated panels strike an excellent balance between factory efficiency and on-site flexibility. These systems adapt to virtually any design while maintaining the benefits of controlled manufacturing.

Wood panel systems lead in residential construction. Entire wall sections arrive with sheathing, insulation, and vapor barriers already installed. Windows and doors might even be pre-hung. Assembly resembles a well-orchestrated dance, with cranes placing panels while workers secure connections.

Concrete panels bring commercial-grade durability to residential projects. These massive elements can include architectural finishes, insulation, and even embedded electrical conduits. The result is a home that’s virtually indestructible yet assembled in days.

Steel panel systems offer incredible strength-to-weight ratios. Light gauge steel framing won’t warp, twist, or rot. Termites and other pests find nothing appetizing. The dimensional stability means doors and windows operate smoothly for decades.

D Printed Houses

The future has arrived with 3D printed construction. Massive printers extrude concrete or specialized materials layer by layer, creating walls with integrated insulation channels and utility conduits.

The speed defies belief. Some systems can print a small home’s walls in under 24 hours. Complex geometries that would challenge traditional construction emerge effortlessly. Curved walls, integrated furniture, and artistic elements cost no more than straight, simple designs.

Cost reduction potential is enormous. Labor requirements drop dramatically—a small crew operates the printer and handles finishing work. Material waste approaches zero since the printer uses exactly what’s needed.

Current limitations include size constraints and the need for traditional roofing and finishing work. However, the technology advances rapidly, with new materials and techniques emerging constantly.

Durable Construction Methods for Long-Term Value

Concrete Construction

Concrete has earned its reputation as the ultimate durable building material. When properly mixed, poured, and cured, concrete structures can last centuries with minimal maintenance.

Fire resistance is absolute – concrete simply doesn’t burn. This provides invaluable peace of mind and often results in lower insurance premiums. In wildfire-prone areas, concrete construction can mean the difference between total loss and minor smoke damage.

Pest resistance is another major advantage. Termites, carpenter ants, and rodents can’t damage concrete. There’s nothing for them to eat, and they can’t tunnel through it. This eliminates a major maintenance concern and potential structural threat.

Natural disaster resilience makes concrete ideal for challenging locations. Hurricane winds that would demolish wood-frame houses barely affect concrete structures. Earthquakes might crack concrete, but proper reinforcement prevents collapse.

Thermal mass provides free climate control. Concrete absorbs heat during the day and releases it at night, naturally moderating temperature swings. This passive temperature regulation significantly reduces HVAC demand.

Steel Frame Construction

Steel framing brings commercial-grade durability to residential construction. The strength allows for expansive open floor plans impossible with wood framing. Want a great room without columns? Steel makes it happen.

Dimensional stability means perfection lasts. Steel doesn’t shrink, swell, or warp with changes in moisture. Doors close properly year-round. Drywall doesn’t crack from structural movement. These might seem like small benefits until you’ve lived with the alternative.

Earthquake resistance is exceptional. Steel’s flexibility allows it to bend without breaking, absorbing seismic energy while maintaining structural integrity. Many earthquake-prone regions now prefer steel construction for this reason.

Design flexibility unleashes architectural creativity. Cantilevers, long spans, and dramatic angles become practical and affordable. Modern homes with walls of glass and floating staircases typically rely on steel’s strength.

Timber Frame with Advanced Treatments

Modern timber frame construction combines traditional beauty with high-tech protection. Today’s treatments transform wood into a material that rivals synthetic alternatives for durability.

Pressure treatment has evolved far beyond the arsenic-laden processes of the past. Modern treatments use copper-based compounds or borates that protect against rot and insects while remaining safe for humans and pets. Some treatments even add fire resistance.

Engineered wood products like glulam beams and cross-laminated timber (CLT) offer strength exceeding traditional lumber. These products resist warping and splitting while allowing for impressive spans and loads.

Natural insulation properties make timber frames energy-efficient. Wood has inherent insulating value, unlike steel or concrete. This means the structure itself contributes to your home’s thermal performance.

The aesthetic appeal remains unmatched. Exposed beams and posts create warmth and character impossible to replicate with other materials. This timeless beauty often translates to higher resale values.

Comparing Construction Types: Which Is Best?

Let’s put everything into perspective with a comprehensive comparison:

Construction Type Sustainability Speed of Build Durability Cost Best Use Case

SIPs Very high – minimal waste, excellent insulation Moderate – faster than traditional High – resistant to settling and warping Moderate – higher material cost offset by labor savings Energy-efficient residential homes in any climate

ICF High – energy efficient, long-lasting Moderate – forming takes time, but goes up quickly Very high – disaster resistant Moderate-high – premium for extreme durability Disaster-prone areas, extreme climates

Modular Moderate – depends on materials used Very fast – concurrent site and building work Moderate – as good as materials chosen Moderate – factory efficiency reduces costs Affordable, quick housing needs

3D Printing Moderate-high – minimal waste, design efficiency Extremely fast – 24-48 hour wall printing Moderate – technology still developing Variable – depends on local availability Experimental and custom architectural designs

Concrete Moderate – high embodied energy, but lasts centuries Slow – forming, pouring, curing takes time Very high – virtually indestructible High – materials and skilled labor Urban and commercial buildings, extreme weather zones

Steel Frame Moderate – recyclable but energy-intensive Moderate – precision speeds assembly Very high – doesn’t degrade High – premium material costs Modern architectural designs, seismic zones

Timber Frame High – renewable, carbon-storing Moderate – traditional joinery takes time Moderate-high – with proper treatment Moderate – varies with wood species Custom homes, eco-friendly builds with character

Factors Influencing Decision Beyond Construction Type

Your local environment plays a crucial role in determining the best construction method. Coastal areas demand materials resistant to salt air and hurricanes. Mountain regions need structures capable of handling heavy snow loads. Desert climates require excellent insulation against extreme heat.

Budget constraints often dictate possibilities. While you might prefer ICF construction, your financing might only cover traditional methods. However, consider lifetime costs carefully. Energy-efficient construction might qualify for green building loans with better terms.

Local expertise matters more than you might think. The best construction method is one your local contractors can execute properly. A perfectly designed steel frame home becomes a disaster if your builder lacks experience with steel construction.

Building codes vary dramatically between jurisdictions. Some areas embrace innovative methods while others strictly limit options. Research local regulations early to avoid costly surprises. Your local building department can provide guidance on acceptable methods and any special requirements.

Practical Tips for Choosing the Best House Construction Method

Start your journey with thorough research. Visit homes built using different methods. Talk to homeowners about their experiences. What do they love? What would they change? Real-world experience beats theoretical knowledge every time.

Consult multiple experts before deciding. Architects, engineers, and experienced builders each bring valuable perspectives. Energy auditors can help quantify efficiency claims. Insurance agents can explain how construction types affect premiums.

If sustainability is a top priority, pursue green building certification. LEED, Energy Star, and Passive House standards provide frameworks for making environmentally responsible choices. These certifications often increase resale value while reducing operating costs.

Balance your immediate needs with future possibilities. That traditional wood frame might seem adequate now, but will it accommodate solar panels later? Could you add a second story if your family grows? Think beyond today’s requirements.