Wiring a generator to your house provides a reliable backup power source during outages, ensuring essential appliances keep running smoothly. This guide covers safe and easy methods to connect your generator, including using transfer switches and generator interlock kits, to help avoid common hazards like backfeeding and electrical overloads. With the right tools and precautions, powering your home generator can be straightforward and secure.

Understanding Generator Wiring Basics

Let’s start with the fundamentals. When we talk about wiring a generator to your house, we’re essentially creating a safe, code-compliant pathway for electricity to flow from your generator into your home’s electrical system. This isn’t as simple as running an extension cord from your generator to your appliances—that approach is both inefficient and potentially dangerous.

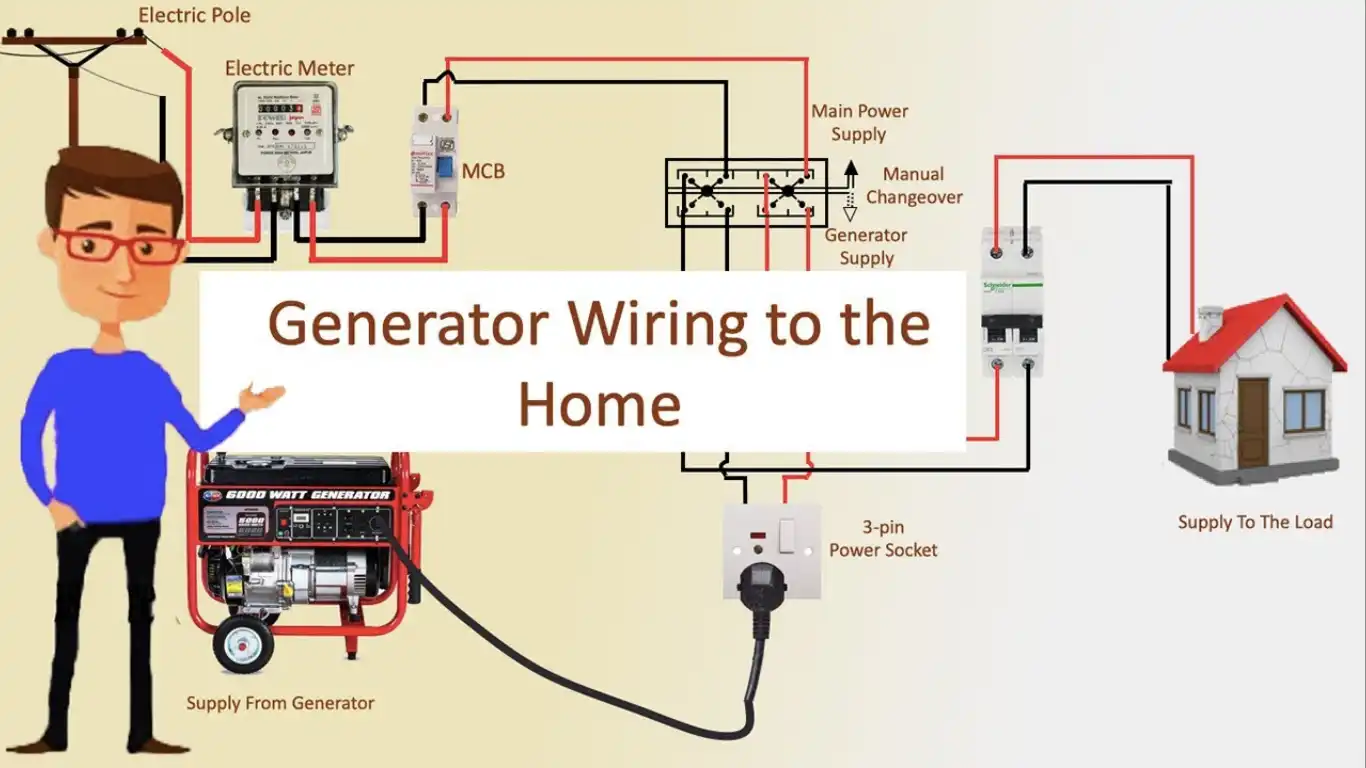

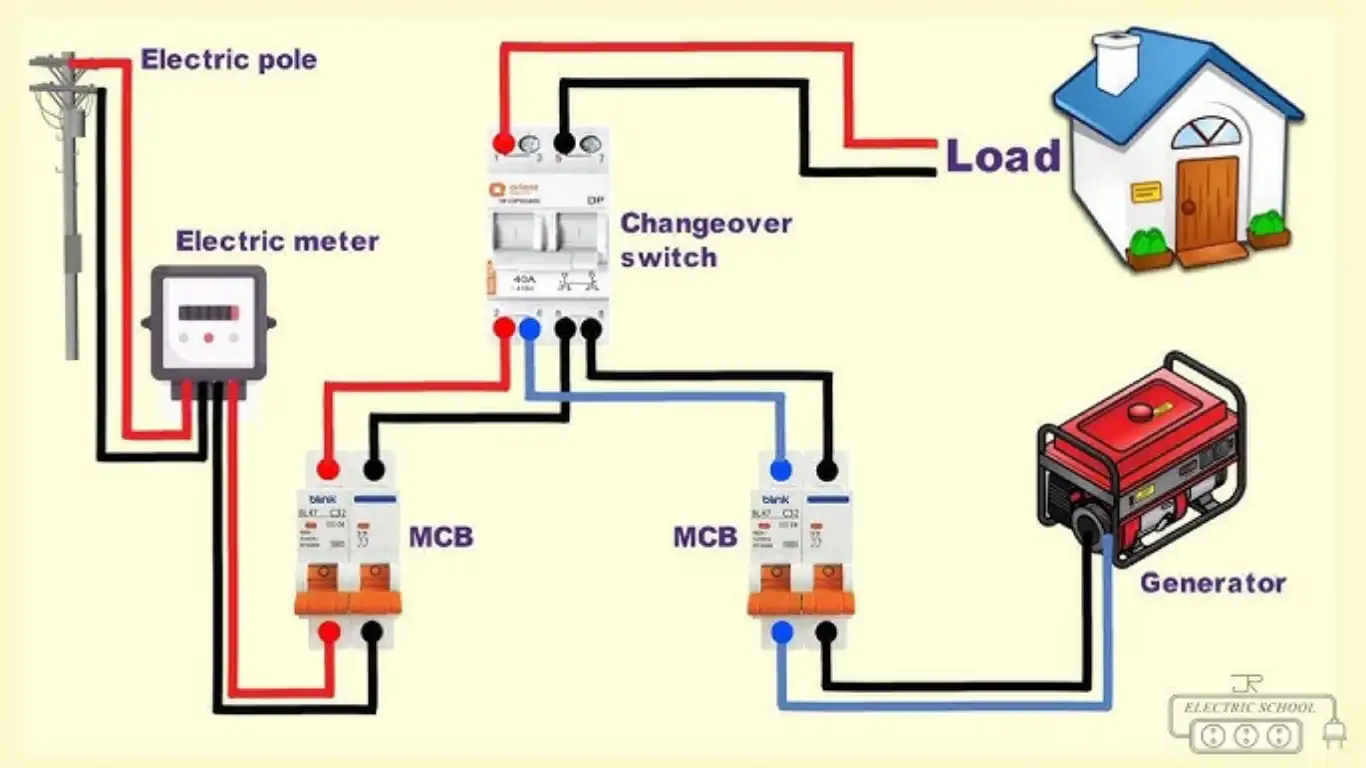

Think of your home’s electrical system like a network of highways. Your main electrical panel acts as the central hub, distributing power throughout your house. When you wire in a generator, you’re creating an alternate route for electricity to enter this hub when the primary power source (the utility grid) becomes unavailable.

Types of Generators for Home Use

You’ve got two leading players in the home generator market: portable and standby generators. Each has its own wiring requirements and considerations.

Portable generators are the workhorses of emergency power. They’re relatively affordable, can be moved around as needed, and typically run on gasoline or propane. These units usually range from 3,000 to 10,000 watts, making them perfect for powering essential circuits during outages. However, they require manual setup and connection when needed.

Standby generators, on the other hand, are the luxury sedans of backup power. These permanent installations automatically kick in when they detect a power outage. They’re connected directly to your home’s natural gas or propane supply, eliminating the need for fuel storage. While they’re more expensive upfront, they offer seamless, hands-free operation that many homeowners find worth the investment.

Basic Electrical Concepts You Need to Know

Don’t worry—you don’t need an electrical engineering degree to understand generator wiring. But grasping a few key concepts will make everything else click into place.

Voltage is like water pressure in a pipe—it’s the force that pushes electricity through wires. Most home generators produce either 120 or 240 volts, matching your home’s standard electrical system.

Amperage represents the amount of electricity flowing through a wire. Think of it as the volume of water flowing through that pipe. Different appliances require different amounts of current, and your wires need to be thick enough to handle the load safely.

Wattage combines voltage and amperage to give you the total power being used or produced. This is what you’ll use to match your generator’s capacity to your home’s needs.

Code Compliance and Regulations

Here’s where things get serious. The National Electrical Code (NEC) sets strict standards for generator installations, and your local jurisdiction might have additional requirements. These codes exist for good reasons—they prevent fires, protect utility workers, and ensure your installation will work safely for years to come.

Most areas require permits for generator installations, especially when you’re connecting to your home’s main electrical panel. Skipping this step isn’t just illegal—it could void your homeowner’s insurance and create liability issues if something goes wrong.

Essential Safety Precautions Before Wiring

Safety isn’t just important when wiring a generator—it’s absolutely non-negotiable. Electricity doesn’t give second chances, and the combination of high voltage and improper installation can be deadly.

The Deadly Danger of Backfeeding

Here’s a scenario that keeps utility workers up at night: backfeeding. This occurs when electricity from your generator flows backward through your home’s electrical system and into the utility lines. What makes this so dangerous?

When utility workers are repairing downed power lines, they assume those lines are dead. Generator backfeed can energize these lines, creating a potentially fatal hazard for anyone working on them. This is why proper transfer switch installation isn’t just recommended—it’s legally required in most jurisdictions.

Backfeeding doesn’t just endanger others. It can also damage your generator and home appliances when utility power is restored, creating voltage surges that destroy sensitive electronics.

DIY vs. Professional Installation

Let’s have an honest conversation about whether you should tackle this project yourself. Electrical work requires knowledge, skill, and respect for the dangers involved. While many homeowners successfully install generator connections, it’s not a project for everyone.

Consider hiring a licensed electrician if you’re uncomfortable working with electrical systems, if your local codes require professional installation, or if you’re installing a complex automatic transfer switch system. The cost of professional installation is minimal compared to the potential consequences of a botched DIY job.

Tools and Materials Needed

Having the right tools and materials isn’t just about making the job easier—it’s about ensuring a safe, code-compliant installation that will serve you reliably for years.

Essential Tools List

Your toolkit should include:

- Non-contact voltage tester (absolutely essential for safety)

- Digital multimeter for precise voltage and continuity testing

- Wire strippers are designed for the gauge of wire you’re using

- Insulated screwdrivers in various sizes

- Torque screwdriver for proper connection tightness

- Cable cutters capable of cleanly cutting heavy-gauge wire

- Fish tape for routing wires through walls

- Level for appropriate mounting from components

- Drill with bits for mounting hardware

Required Materials

ComponentPurposeTypical Specifications

Transfer Switch Safely switches between utility and generator power, 30-50 amp rating for most homes.

Generator Inlet Box External connection point for generator NEMA 3R or 4X rated for weather resistance

Power Cord: Connects the generator to the inlet box; 10-gauge or heavier, appropriate length.

Circuit Breakers Protect circuits from overload, matched to your transfer switch rating.

Grounding Rod Provides a safe electrical ground: an 8-foot copper rod, 5/8″ diameter minimum.

Wire carries power between components: 10 AWG or heavier, THHN/THWN-rated.

Sourcing Quality Materials

Don’t be tempted by bargain-basement electrical components. Quality materials are your insurance policy against future problems. Stick with recognized brands and buy from reputable electrical supply houses or home improvement stores.

When selecting wire, pay attention to the gauge (thickness) and insulation rating. Undersized wire can overheat and cause fires, while improper insulation can break down over time. Follow NEC guidelines for wire sizing based on your generator’s output and the distance between components.

Budget Considerations

A complete generator wiring setup typically costs between $500 and $2,000 for materials, depending on your home’s size and the complexity of the installation. Here’s a rough breakdown:

- Manual transfer switch: $200-$400

- Automatic transfer switch: $500-$1,500

- Inlet box and accessories: $50-$150

- Wire and conduit: $100-$300

- Circuit breakers: $50-$150

- Miscellaneous hardware: $50-$100

Professional installation adds $500-$2,000 to the cost, but remember—this investment protects your home and family while ensuring code compliance.

Step-by-Step Guide: How to Wire in a Generator to Your House

Now we’re getting to the heart of the matter. This detailed walkthrough will guide you through each phase of wiring a generator to your house safely and effectively.

Choose the Right Generator and Capacity

Selecting the appropriate generator is like choosing the right engine for your car—too small, and you’ll struggle; too large, and you’re wasting money. Start by calculating your power needs during an outage.

Please make a list of essential appliances and their wattage requirements. Your refrigerator might need 800 watts, your furnace blower 700 watts, and your well pump 1,500 watts. Add these up to determine your minimum generator size. Remember that some appliances require extra starting watts—motors can draw two to three times their running wattage when starting up.

Here’s a practical approach: most homes can manage essential circuits with a 7,500 to 10,000-watt generator. This provides enough power for your refrigerator, heating system, some lights, and a few outlets without breaking the bank.

Consider fuel availability, too. Gasoline generators are standard and affordable but require fuel storage and regular refueling during extended outages. Propane models offer longer shelf life for fuel and cleaner operation. Natural gas generators provide unlimited runtime but require professional gas line installation.

Select the Proper Transfer Switch

The transfer switch is the heart of your generator connection system. This critical component ensures that your generator and utility power never connect simultaneously, preventing dangerous backfeed and equipment damage.

Manual Transfer Switches

Manual transfer switches require you to physically flip switches to transfer power sources. They’re more affordable and give you complete control over which circuits receive power. During an outage, you start your generator, then go to the transfer switch and flip each circuit breaker from “utility” to “generator” position.

The beauty of manual switches lies in their simplicity. There’s less to go wrong, and you can prioritize power distribution based on your immediate needs. They’re perfect for homeowners who don’t mind a hands-on approach and want to save on installation costs.

Automatic Transfer Switches

Automatic transfer switches are the set-it-and-forget-it solution. They constantly monitor utility power and automatically start your generator when an outage is detected. Within seconds, power is restored to your selected circuits without you having to lift a finger.

These systems shine during extended absences or for households with elderly or disabled residents who might struggle with manual switching. The convenience comes at a price, though—automatic switches cost significantly more and require professional installation in most cases.

When selecting your transfer switch, match its amperage rating to your generator’s output and your home’s electrical service. A 30-amp switch works for smaller generators, while larger homes might need 50-amp or even 100-amp switches.

Prepare the Installation Area

Location, location, location—it matters just as much for generators as it does for real estate. Your generator needs to be close enough for practical connection but far enough to ensure safety.

Position your generator at least 10 feet from any building opening, including windows, doors, and vents. Carbon monoxide from the exhaust is deadly, and it can accumulate quickly in enclosed spaces. Some local codes require even greater distances, so check your regulations.

Create a level, stable platform for your generator. A concrete pad works best for permanent installations, while portable generators can use gravel or paver bases. Ensure proper drainage to prevent water accumulation around electrical components.

Install your inlet box on an exterior wall, ideally close to your main electrical panel, to minimize wire runs. The box should be easily accessible but protected from direct weather exposure. Mount it at least 18 inches above ground level to prevent snow burial or flood damage.

Consider noise levels too. Generators are loud, and your neighbors won’t appreciate a roaring engine at 3 AM. Position the unit away from bedroom windows and consider sound-dampening enclosures if noise is a concern.

Connect the Generator to the Transfer Switch

Now we’re connecting the dots—literally. This step brings your generator into the system and requires careful attention to detail.

Run appropriate gauge wire from your transfer switch to the inlet box. For most residential installations, 10 AWG wire handles 30-amp circuits, while 6 AWG is needed for 50-amp connections. Use conduit to protect the wire, especially where it passes through walls or runs underground.

At the inlet box, connect the wires according to the manufacturer’s color coding. Typically:

- Black and red wires carry the two hot legs

- The white wire serves as neutral

- Green or bare copper provides ground

Install a dedicated ground rod for your generator system if required by local code. Drive an 8-foot copper rod into the earth near your generator location and connect it with 6 AWG copper wire. This provides a safe path for fault currents, reducing the risk of electrical shock.

Your generator cord needs to match your inlet box configuration. Most use NEMA L14-30 or L14-50 twist-lock plugs that prevent accidental disconnection. Inspect the cord regularly for damage—a compromised cord is a serious safety hazard.

Double-check all connections with your multimeter before proceeding. Verify continuity on each conductor and ensure there are no short circuits between conductors.

Test the System

The moment of truth has arrived. Testing your installation confirms everything works properly and safely.

Start with the generator disconnected and utility power restored. Verify that all circuits function normally through the transfer switch in the utility position. Each circuit should operate exactly as it did before installation.

Now for the generator test. With the main breaker off, start your generator and let it warm up for a few minutes. Connect the generator cord to both the generator and the inlet box, ensuring twist-lock connections are fully engaged.

At the transfer switch, move each circuit from the utility to the generator position one at a time. Monitor the generator’s response as you add loads. You should see stable voltage (120/240V) and hear the engine adjust to changing demands.

Test each circuit individually, then try combinations of circuits. Your generator should handle the load without struggling or producing voltage fluctuations. If the lights dim significantly when the motors start, you might be overloading the system.

Document your test results, noting which circuit combinations work well together. Create a priority list for power management during actual outages. This preparation pays dividends when you’re dealing with a real emergency in the dark.

Common Mistakes to Avoid

Even experienced DIYers can stumble when wiring generators. Learning from others’ mistakes can save you time, money, and potentially your life.

The Backfeeding Trap

We’ve mentioned backfeeding before, but it bears repeating because it’s the most dangerous mistake you can make. Some people try to save money by skipping the transfer switch and simply plugging their generator into a dryer outlet with a homemade “suicide cord.”

This practice is called suicide cord for a reason. It can kill utility workers, destroy your generator when power returns, and violate numerous electrical codes. There’s no safe way to backfeed—always use a proper transfer switch.

Wire Gauge Miscalculations

Undersized wire is like trying to force a river through a garden hose. The wire overheats, insulation melts, and fires can result. Always calculate the voltage drop along your run and size the wire accordingly.

Many homeowners assume that if a wire fits in the terminal, it’s the right size. This is dangerously wrong. A 30-amp circuit requires 10 AWG wire minimum, even if 12 AWG physically fits in the connections.

Ignoring Grounding Requirements

Proper grounding isn’t optional—it’s a critical safety component. Some portable generator users skip grounding because the generator has rubber feet or sits on non-conductive surfaces. This is a potentially fatal mistake.

In most installations, your generator needs a dedicated ground rod. The frame must be bonded to this ground, providing a safe path for fault currents. Without proper grounding, you become the path of least resistance for electrical faults.

Overloading the System

It’s tempting to power everything with a generator, but overloading can cause numerous problems. Voltage drops damage sensitive electronics, overheated generators fail prematurely, and circuit breakers trip when you need them most.

Be realistic about your generator’s capacity. Running at 80% of rated capacity provides a safety margin and extends equipment life. If you need more power, get a bigger generator rather than pushing a smaller one beyond its limits.